Book stacker BSS-10 |

|

The BSS-10 book stacker allows non-stop Smart-binder operation without the need for the operator to continually have to remove books from the delivery conveyor. Book entry from the SB delivery

Book stack delivery

BSS-10 book stacker: for in-line connection to the Smart-binder delivery conveyor

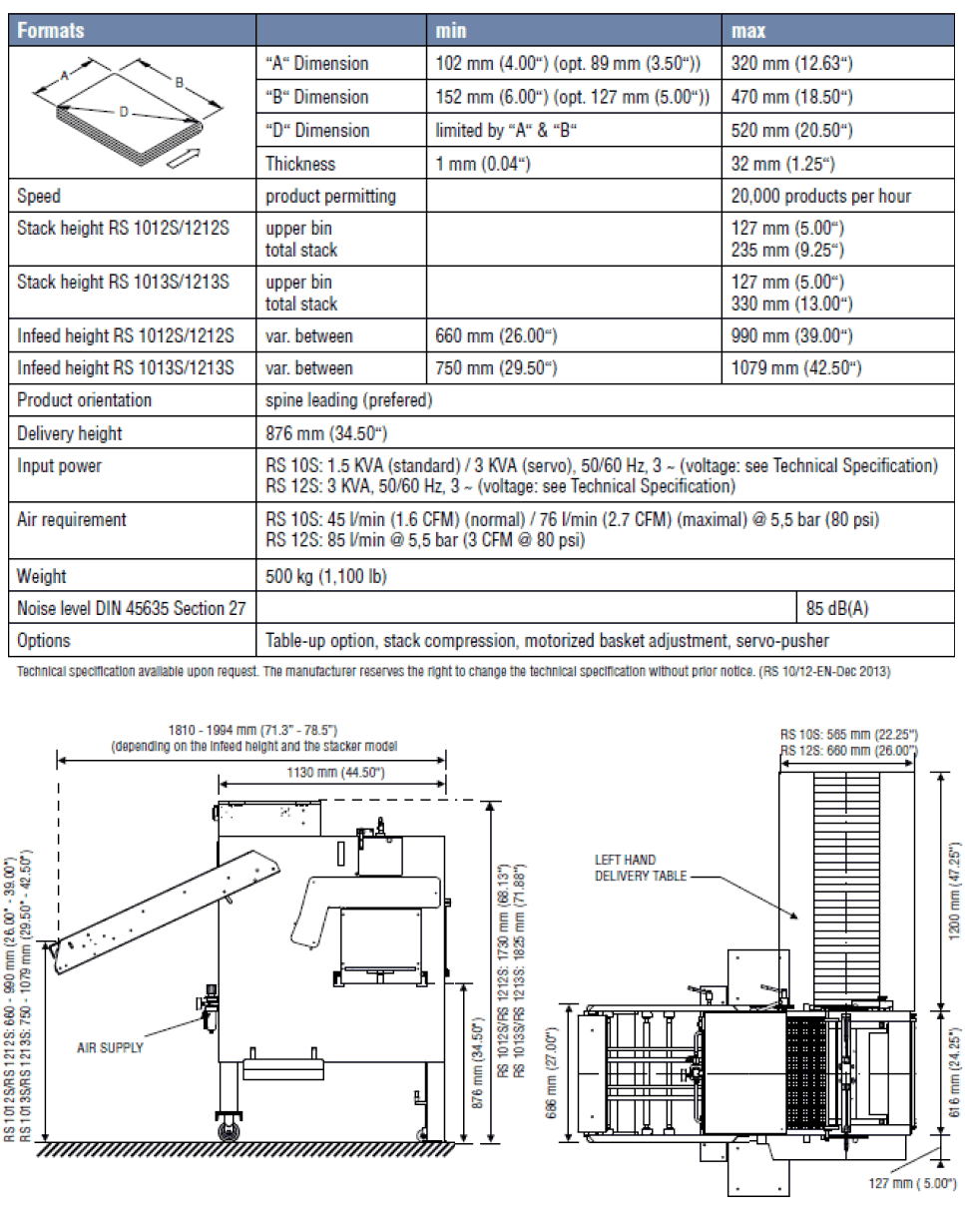

Books pass through the standard Smart-binder delivery conveyor into the BSS-10 stacker where they collect into horizontal piles up to 235mm (9.25") height (or special option up to 330mm -13" height). The number of books in each pile is selectable by the machine operator. A turntable in the stacker enables books within each pile to be stacked in batches with spines in each batch in the opposite direction to the spines in the next batch. This ensures pile stability by avoiding all the spines being on the same side. Book piles are delivered onto a free running roller table where they accumulate until removed by the operator. In-line (or off-line) pile 'banding is also available BSS-10 stacker description of operation 'Intelligent stacking' option SBCR-100An optional bar code reader may be supplied to read a bar code on

each booklet. An additional control system may then be programmed

to use the bar code data to create stacks which contain specific booklets

or signatures. This may be used for example to create stacks of signatures

(book blocks) for subsequent perfect binding, or to create stacks

of booklets in specific 'sets'. BSS-10 stacker specifications

Additional BSS-10 Technical Data |