IBIS CIF-102 datasheet

Cover Feeder

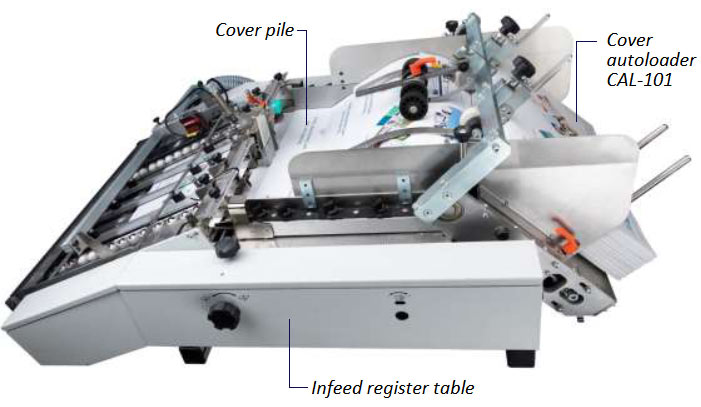

The CIF-102 Cover/Inserter Feeder is designed to feed separately

printed booklet covers or ‘insert sheets' as part of a booklet

assembled by the IBIS Smart-binder. The CIF-102 is mounted on slide

rails over the Smart-binder infeed register table, and will feed a

cover/insert at the appropriate place in the sheet stream passing

below.

The CIF-102 feeds sheets from the bottom of the pile using a rotating vacuum wheel. Air-blow nozzles mounted at the sides and rear of the feeder help separate sheets from each other in the pile. Covers/inserts may be reloaded on-the-run without stopping the Smart-binder.

The maximum pile height in the CIF-102 feeder is about 20 mm. This may be increased to about 200mm with the addition of the optional Autoloader CAL-101.

Covers (or inserts) are independently side-registered so that their width does not have to be the same as the width of the digitally-printed 'content' sheets. However the covers (or inserts) must be the same length as the sheets on to which they are fed (same spine length). Covers or inserts that are longer or shorter than the other sheets in the book will cause some loss of print registration between sheets.

If running covers with cut-out windows, then IBIS can supply an extra part (made to suit the dimension of the window) to assist feed and prevent the windows in the cover being fed catching on the window of the cover above.

After side register, then covers (or inserts) enter the Smart-binder scoring and folding module. Scoring pressure may be adjusted to minimize color-toner cracking. However, the optimum way to eliminate cracking is to pre-crease the covers.

A bar-code reader is available for the cover/insert feeder if feeding personalized covers or insert sheets. The cover/insert feeder will then compare the unique ID number in the cover/insert barcode to the ID number in the barcode on the incoming sheets. The Smart-binder can be programmed to either stop on a mismatch, or reject the booklet (without stopping) via the trimmer reject gate. The standard bar code reader is option BCR-105. Choose the 2D Datamatrix reader DCR-101 if the 2D codes are to be used.

The cover and insert feeder CIF-102 is capable of feeding sheets in the range 70 - 230 gsm (47 - 154 lbs offset or 19 -61 lbs bond). Covers outside this weight range should be tested before use to check feeding performance.

If feeding covers or inserts from the CIF-102 feeder and making ISG cold-glued books, then there must be sufficient space between the last sheet of one book and the first sheet of the next book into which to feed the cover or insert sheet. If running in-line with a high-speed digitally-printed web, then this may mean that the web cutter must be programmed to pause momentarily, in order to create this gap. If feeding from a pile feeder, then the gap in sheet feeding can be created automatically by the Smart-binder feeder control system. This gap is also required if feeding an insert sheet into the center of a booklet (center-spread).

A dual cover feeder system may be fitted (one behind the other: CIF-102 + CIF 101) if wishing to feed both an insert sheet in addition to a cover sheet, or if wishing to split cover feed between two feeders.

Covers with tear-off perforations may be run depending on the type and position of the perforations. Check with IBIS first if wishing to feed perforated covers. Note that an optional 'dynamic' micro-perforation system (option DMP-100) is available for installation just before the Smart-binder folder. This may be used to automatically perforate covers (and/or all other sheets within the booklet) if not already pre-perforated.

Covers with 'gate' folds (or 'wing' folds) have an extra folded "flap? on one or both sides which make them difficult, or in some cases impossible, to feed. These types of covers may contain 6 or even 8 printed pages.