Four Printers share their Digital Finishing Success Stories for High-Speed Inkjet

By Julie Greenbaum

The article was posted in www.PiWorld.com in February 2017

Since adding digital finishing equipment into their production inkjet workflows, the following four printing establishments have been able to better meet their customers’ deadlines and requirements, have been able to take on new work they could not do before, and have significantly eliminated the manual steps that were previously required to complete a job.

The article continues with texts about printer companies 'NMD&D' and 'Allied Priner', view in the full article HERE

and then presents printers "John Patrick Publish Co." and " Liturgical Publications (LPi)" that use IBIS machines, as below:

Founded in 1992, John Patrick Publishing Co. (JPPC), in Trenton, N.J., prints weekly bulletins and publications for more than 500 churches throughout the United States. The 8.5x11?-format page counts are generally between eight and 16 pages, with average run lengths less than 1,000 bulletins. In addition to weekly bulletins, JPPC provides many other printed communication products for parishes, along with website development services.

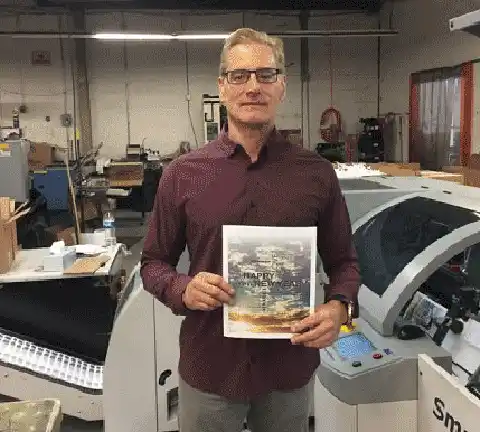

John Patrick Publishing Co. CEO John Hartmann

In 2015, JPPC CEO John Hartmann made the decision to convert print production to digital. He invested in an HP T Series PageWide inkjet web press, Tecnau web processing equipment and a near-line IBIS Smart-binder SB-3 Plus HS, which was installed in the summer of 2016. The paper rolls are printed on the HP inkjet web press and unwound and cut into sheets by a Tecnau web cutter from where the sheets flow directly into the Smart-binder.

Hartmann describes the Smart-binder as a heavy-duty, fast saddle stitcher, which allows for frequent changes in booklet pagination. It plays a key role in meeting the requirement for on-time delivery of the company’s short-run bulletin documents.

“Prior to using the Smart-binder, we had to use several pieces of equipment depending on the final finished format. Now, anything other than a job that requires four to six pages or more, goes on the Smart-binder and we can just process rolls, one right after the other. It’s really been phenomenal,” he says.

Using the HP T Series web press, Hartmann notes that jobs can be moved around in the queue, then placed on rolls and then taken to the Smart-binder. The Smart-binder has also allowed the printer to print larger bulletins up to 24 pages. The company also brings in outside work that requires more pages and the IBIS can handle 36- and 48-page books without a problem.

“Our capabilities have been enhanced in the commercial work we produce to allow us to run much larger books,” Hartmann concludes. “We are producing about 200 of them, and the Smart-binder has simplified the process. It reads the barcode and finishes the book. It’s pretty incredible.”

Full-Color Church Bulletin Booklets

Another producer of church bulletins, Liturgical Publications (LPi), in New

Berlin, Wis., was also looking for a way to simplify the finishing process.

The company grew from producing a one- to two-color product — four to six

pages in size — to full-color, 16- to 32-page booklets. The color complexity

and need for quality and consistency required that LPi explore different technologies

to meet its customers’ demands.

The company invested in an IBIS Smart-binder SB-2 with cover feeder, stitching and three knife trimmer, and is also using a Tecnau 568 system for in-line saddle stitching which also generates individual sheets for stitching or neat paper stacks for book blocks. A Baum 20INF in-line folder, with a Tecnau TC 1550 FL1 W dynamic perforator, allows for tear-out coupons to be integrated into the printed product. On the press end, the company operates an HP PageWide T230 inkjet web press (roll-to-roll) and a Konica Minolta bizhub PRESS C7000/P cut-sheet color digital press.

Originally, LPi considered utilizing Tecnau’s in-line equipment but decided to go with a roll-to-roll configuration with near-line finishing to increase efficiencies and reliability. The Tecnau 566 stacker builds 8.5? stacks either one-, two- and three-up, to be transported to near-line or off-line finishing units, such as the perfect binders.

LPi began printing church bulletins more than 40 years ago, and the family-owned company continues to grow that core business. The bulletins and newsletters are produced on a weekly or monthly basis to its customer base of more than 4,000 churches across the United States. Headquartered outside of Milwaukee, the company operates satellite offices in Cleveland; Hartford, Conn.; Orlando, Fla.; and Denver to better serve customers in those regions. Other products and services LPi provides for parishes and religious organizations include newsletters, ministry directories, welcome packets, calendars and website design and hosting.

According to Ken Hause, pressroom supervisor, issues that existed prior to installing the new digital finishing equipment have since been resolved. He reports an increase in uptime, speed and productivity; a decrease in errors, reprints and overages; more staging space for jobs to be collated and folded; and the ability to better meet customer deadlines. In addition, minimal maintenance is needed on the equipment.

“The digital finishing equipment has smoothed out the production process tremendously,” Hause concludes. “Integration of the data needed for a given job is done through a barcode. In addition, because we are running our press roll-to-roll and the fact that our average run length is 800, transitions from job to job are seamless.”

Julie Greenham