|

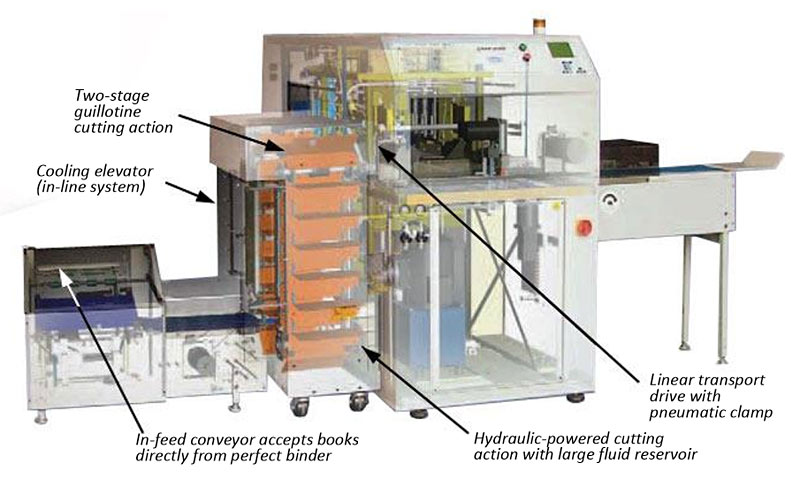

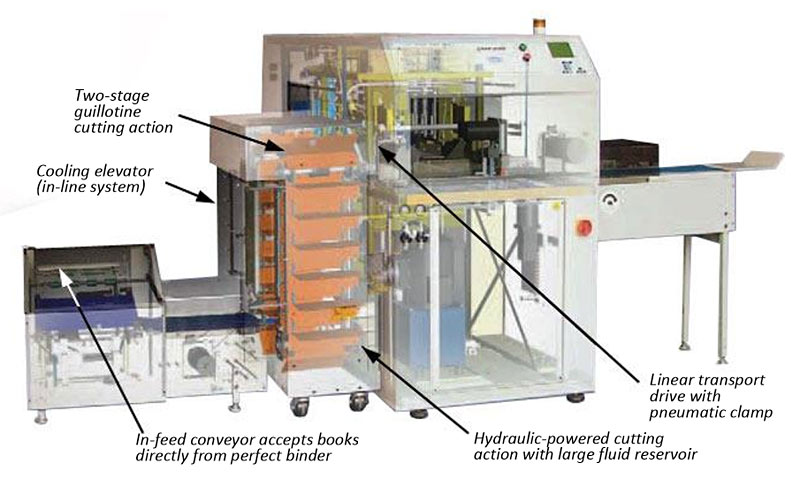

The CMT 330 three-knife trimmer finishes soft-cover, perfect

bound books at a rate of up to 400 cycles per hour. Designed for on-demand

printing, it can be used in-line with perfect binders or near-line

in a manual-feed mode. By trimming 2-up or 3-up, books may be

processed at a rates of 800 or 1200 books/hour.

In-line version CMT-330 (for direct feed from a perfect

binder)

The CMT-330 3-knife trimmer is offered for use after

a perfect binder in order to cut books to required finished format

size. The in-line version shown above connects directly to the

perfect binder outlet, and includes a multi-stage book cooling elevator

to allow time for the hot-melt glue to cool before trimming.

The CMT-330 has a maximum book thickness limit of 51mm

(2").

CMT-330 Features and Specifications

- Trimmed Book Sizes: 4" x 6" to 9" x 12"; up

to 2" thick

- Available with In-line or Near-line Configurations

- Full Digital Control for Fast, Accurate Changeovers -Knives and

Clamps Reposition in 15 Seconds

- Requires No Special Tools or Clamp-boards when Changing Book Sizes

- Computer-Controlled Servomotors Adjust Knives

- Easy to Use and Program

- Light-Touch Electronic Keypad

- Menu-Driven LCD Data/Graphic Screen

- 99-Job Memory

- Computer Diagnostics

- Minimal Maintenance Requirements

- Hydraulic Cutting

- Adjustable Clamp Pressure

- Adjustable Pneumatic Gripper Pressure

- Rugged Construction

- UL Listed (USA and Canada)

Full Digital Control

The

CMT 330 features full digital control of the trimming process,

which results in significant time savings over traditional trimmers.

Just key in the starting size and the finished size, and the computer-controlled

servomotors automatically adjust knives and clamps to the correct

positions in only 15 seconds. The

CMT 330 features full digital control of the trimming process,

which results in significant time savings over traditional trimmers.

Just key in the starting size and the finished size, and the computer-controlled

servomotors automatically adjust knives and clamps to the correct

positions in only 15 seconds.

The CMT 330's control panel includes a menu-driven LCD

screen that makes setup very easy. It summarizes job names, displays

programming, and lets you direct other machine functions. A light-touch

electronic keypad allows easy programming in decimals, fractions,

or metric equivalents. Cursor controls and four selection keys speed

navigation through other machine functions.

The CMT 330 can store up to 99 jobs in its memory for even faster

setup. A serial communication port permits remote setup and control

for in-line use in fully automated bookshop environments.

Designed for Safety and Convenience

- Knives are easily accessible for fast, efficient changes. For

added safety while changing knives, a custom designed guard shields

the knife edge.

- Infrared sensors monitor each of three waste bins and generates

a display on the control panel when a bin is full.

- Levelling feet provide greater stability, and are adjustable to

help compensate for uneven floors.

- A multi-station cooling elevator (for in-line systems) allows

ample glue set-up,cooling, and drying time before books are trimmed.

Built to Last

The CMT 330 features solid construction and requires minimal maintenance.

A steel frame, large hydraulic cylinders, and heavy-duty components

help ensure long life. Hydraulics offer low-maintenance, trouble-free

operation.

Capable and Reliable

The CMT 330 offers convenience, efficiency, and durability.

CMT-330 Inline Configuration with Cooling Tower

|

The

CMT 330 features full digital control of the trimming process,

which results in significant time savings over traditional trimmers.

Just key in the starting size and the finished size, and the computer-controlled

servomotors automatically adjust knives and clamps to the correct

positions in only 15 seconds.

The

CMT 330 features full digital control of the trimming process,

which results in significant time savings over traditional trimmers.

Just key in the starting size and the finished size, and the computer-controlled

servomotors automatically adjust knives and clamps to the correct

positions in only 15 seconds.