Document edge sealer DES-100 |

The DES-100 document Edge Sealer module may be connected directly (in-line) to the end of the Smart-binder delivery conveyor.

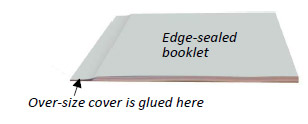

Booklets are made on the Smart-binder with a cover width greater than the inside sheet width.

![]()

The upper cover is lifted up by the DES-100 vacuum opener device and hot melt glue is applied to the inside edge of the lower cover using the Robatech nozzle (Concept B5/2-ASIK40/2-SX1S Diamond)

The upper cover is then closed again and pressed onto the glued lower cover in order to seal the booklet.

![]()

trimmer

or spine-glued

booklets from

the IBIS Smart-binder

sealer module

delivered into optional delivery 'tray'

After being edge sealed the booklet may only be opened by ‘tearing’ the sealed foredge. The DMP-100 dynamic perforator may be used to perforate the cover to allow the glued edge to be more easily torn off, if required. Alternatively a type of glue may be used which allows the booklet to be ‘peeled’ open.

The

edge sealing process may be used to secure confidential documents

containing sensitive information (such as exam papers) so that these

documents cannot be easily viewed without leaving evidence that the

document has been tampered with. It may alternatively be used to allow

booklets to be self-mailed without opening up in the postal system.

The

edge sealing process may be used to secure confidential documents

containing sensitive information (such as exam papers) so that these

documents cannot be easily viewed without leaving evidence that the

document has been tampered with. It may alternatively be used to allow

booklets to be self-mailed without opening up in the postal system.

DES-100 specifications

- Length: 1875mm, Width: 830mm

- Max Speed: 100 m/min

- Max book processing rate : 100 books/min

- An optional booklet delivery tray is available (or may deliver to optional BSS-10 stacker)

- Controls: 2 x on/off pushbuttons for main motor and vacuum pump + 2 x E stops

- Elect supply: 230 V, 50/60 Hz, 10 Amps

- Glue applicator : Robatech Concept B5/2-ASIK40/2-SX1S Diamond + photocell + pattern controller

- Air requirement : dry air @ 6 bars (90 PSI)