Producing Extended Content Label (ECL) booklets using the Smart-binder |

Download ECL Booklets Data Sheet

The IBIS Smart-binder presents an ideal way to produce ‘Extended Content Label' booklets from digital printed sheets:

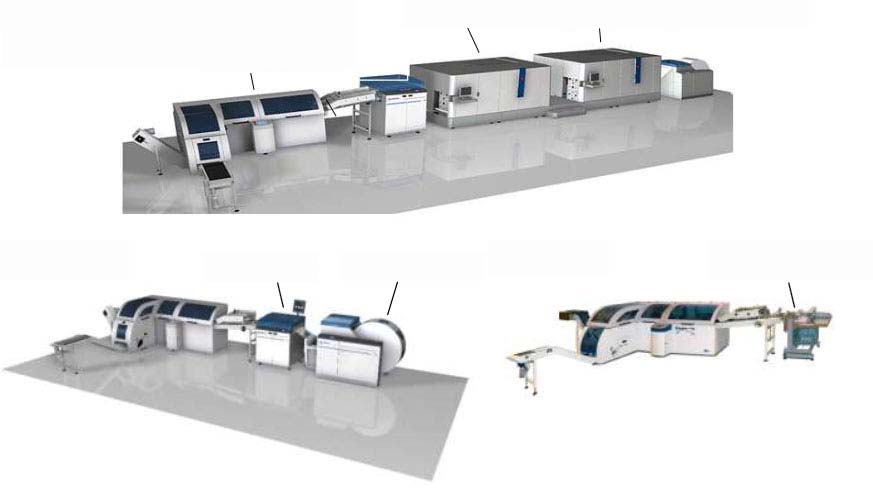

Typical ECL booklet production lines

IBIS Smart-binders are used for ECL production for the following reasons:

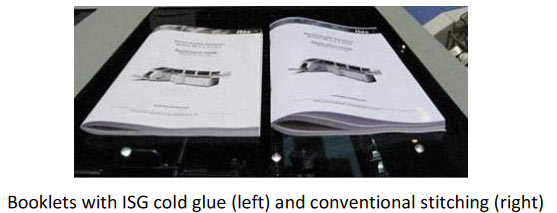

1/ ISG cold glue binding

Label booklets which are to be attached to end-product containers, such as may contain pharmaceuticals or agro-chemicals, are often not suitable for conventional wire stitching. In this case IBIS's unique and patented ISG cold glue system provides a more suitable and higher quality binding alternative to wire stitching.

IBIS Smart-binder ISG Cold Glue binding ISG-100

Cold-glue binding is essential for many ECLs, the use of a conventional wire stitching is not an option for these label booklets. Most label manufacturers insist on using ISG cold glue to bind their ECLs instead of wire stitching for the following reasons:

- ISG cold glue binding gives improved booklet ‘lay-flat’, which helps subsequent processing of these labels and attachment to the product container

- The lack of wire in the booklet is important (and essential in some case) for labels that are attached to product containers. Glue bound labels are easier to recycle if they do not contain wire staples

- The ISG cold glue system is easier to use and to maintain compared with wire stitch heads

2/ Label Integrity

Each label must contain the correct data relating to the product to which it is attached. Each type of ECL lable (for a specific product) may have an individual ID number in the printed bar code (or 2D Datamatrix code) on each sheet. The Smart-binder reads these sheet codes and uses its sophisticated integrated sheet and booklet tracking system and sensors to monitor the status of each Label booklet and automatically reject any ‘bad’ booklets. The Smart-binder control PC retains log files containing production data relating to each booklet produced, or rejected. The production log files may be viewed externally with a network connection if required. If any booklets are missing on the delivery then these must be reprinted. The optional SDA-100 Smart-Data Analysis system assists with the upstream interface to enable this automatic reprinting of any missing Labels.

3/ Small Format Sizes

Many ECL labels have a small format size because of the small dimensions of the product to which they are subsequently attached. For this reason the Smart-binder can be supplied with special modifications to reduce the minimum booklet width to 75mm (measured from the spine to the front edge).

IBIS video: Smart-binder producing 75mm wide ECL labelsVery short spine lengths can be achieved very efficiently by printing multiple booklets together (multi-up). For example six ECLs with a 2” spine length may be printed on a 12” long sheet. The resulting 12” long booklet is then split into the 6 individual booklets after exiting the Smart-binder. Note that booklets with spine lengths between 95 and 160mm may be produced 2-up without needing any further trimming, by using the optional Smart-binder trimmer center-knife.

The additional TP-100 book splitter may be added the Smart-binder delivery to cut long booklets into multiple short booklets of any required length.

4/ Low Stock Weight

ECL labels often require a low stock weight material in order to minimize the overall label thickness and in some cases to assist it to bend around the product to which it is attached. The Smart-binder can be offered to run stocks as light as 45gsm.

5/ ECLs with tabs

Some ECLs may require tabs on the front cover as shown below:

The tabbed cover may be fed from the optional Smart-binder cover feeder providing that the stock weight is not too low.

IBIS video: Smart-binder producing ECL label booklets with tabs on the front edge6/ High Reliability with Minimum Maintenance

Machine ‘availability’ (up-time) is of course important for all ECL label production. The Smart-binder is a very heavy-duty system designed to operate 24/7 with the minimum of maintenance and with the highest possibility reliability.

7/ Ability to Change the Number of Pages on the Run

Some ECLs may need to be produced in very small job quantities. The Smart-binder allows the number pages in the ECL to change between one job and the next without stopping, under bar-code control.

View the IBIS Smart-binder system in operation

Case Studies

Each of the following customers are using the IBIS Smart-binder to produce ECL booklets.

Case study 1: Company XYZ (name withheld for confidentiality reasons)

XYZ have purchased IBIS Smart-binders to produce ECL booklets at multiple locations around the world, fed both off-line from a sheet feeder and also near line from a roll unwinder and web cutter. They have also developed a special system to provide cover ‘tabbing’

Case study 2: Codex, Hungery

Codex purchased an off-line Smart-binder system with ISG cold-gluing in 2020.

Janos Toth, Production Manager, comments as follows

![]() Our new IBIS Smart-binder SB-3 was installed here at Codex just outside Budapest in the spring of 2020. The machine processes our digitally-printed sheets using its integral high-pile sheet feeder and we are pleased with the SB-3 performance and robust design.

Our new IBIS Smart-binder SB-3 was installed here at Codex just outside Budapest in the spring of 2020. The machine processes our digitally-printed sheets using its integral high-pile sheet feeder and we are pleased with the SB-3 performance and robust design.

The SB-3’s ability to produce large volumes of high value, high quality pharmaceutical booklets, instruction manuals and label booklets at high speeds is critical to our business.

The SB-3’s patented ISG cold-glue binding process gives good bind strength and booklet lay-flat, so is popular with our label customers. ![]()

Case study 3: Decomatic, France

Decomatic purchased an off-line Smart-binder in 2023 with special modifications to reduce the minimum ECL booklet width to 75mm and to feed tabbed covers from the cover feeder. This system includes the optional Smart-binder trimmer center-knife.