Insurance policy booklet production using the Smart-binder |

Download Insurance Policy Booklets Data Sheet

The IBIS Smart-binder is frequently used to produce personalized insurance policy booklets from digital printed sheets:

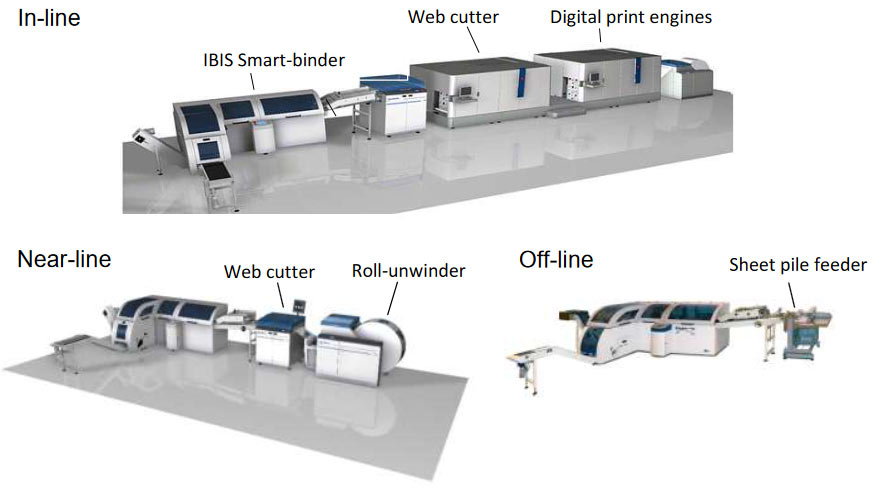

Typical insurance policy booklet production lines

Here are some reasons why IBIS Smart-binders are so well suited for producing all different types of personalized insurance policies, including 'healthcare' insurance:

1/ Booklet integrity

It is essential that an insurance policy document contains all the required printed policy data for a particular individual and there is nothing missing or added. Each booklet has an individual ID number in its printed bar code (or 2d Datamatrix code) on each sheet. The Smart-binder reads these sheet codes and uses its sophisticated integrated sheet and booklet tracking system and sensors to monitor the status of each booklet and automatically reject any 'bad' booklets. The Smart-binder control PC retains log files containing production data relating to each booklet produced, or rejected. The production log files may be viewed externally with a network connection if required. If any booklets are missing on the delivery then these must be reprinted. The optional SDA-100 Smart-Data Analysis system assists with the upstream interface to enable this automatic reprinting of any missing booklets.

2/ Personalized Addressing and Mailing

If each policy is unique and intended for one specific individual then it will either require the individual's name and address to be visible on the outside of the booklet (for example in the USA to allow direct mailing to that individual) or it will need to be inserted into an addressed envelope (sometimes together with other materials).

The Smart-binder cover feeder can feed a different (usually heavier) stock cover with the name/address printed on it and an additional code reader in the cover feeder can check that the ID number on the cover 'matches' the ID number on the inside sheets. If the two coded numbers do not match then the machine stops to allow the operator to regain correct cover sequence.

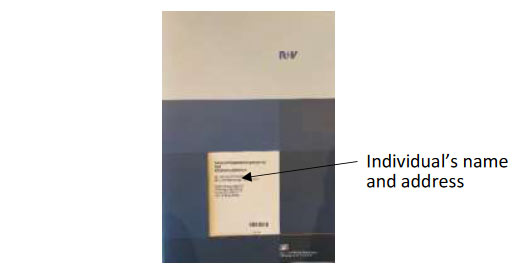

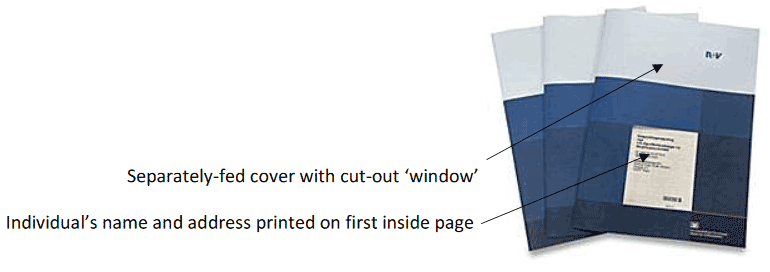

Alternatively (and preferably) the cover can have a cut-out window in the front to allow the printed name/address on the next sheet to be visible from the outside. See R & V insurance policy example below:

The IBIS Smart-binder can be fitted with a device to ensure that covers with windows feed reliably from the cover feeder. This device must be custom-made to suit the size of the window.

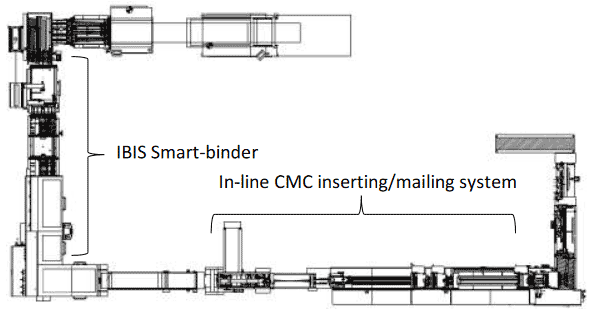

The IBIS Smart-binder can interface with a variety of different in-line Mailing systems (such as those made by Kern, CMC or KAS). In this case each finished booklet enters the Mailing machine, changes direction, inserts are added, the booklet is closed and inserted into an envelope. See floorplan below:

3/ High reliability with minimum maintenance

Machine 'availability' (up-time) is of course important for all high-volume insurance document production. The Smart-binder is a very heavy-duty system designed to operate 24/7 with the minimum of maintenance and with the highest possibility reliability.

4/ High web speeds and ability to change the number of pages on-the-run

Some insurance policies contain a large range variability in total number of pages. The IBIS Smart-binder's ability to allow the number of pages in each booklet to vary 'on the run' is therefore essential and also its ability to maintain a high input speed (web speed of sheet feed rate) while varying pagination. Typically the Smart-binder will produce around 7,000 insurance booklets/hour when making thinner policies (8 - 12 pages).

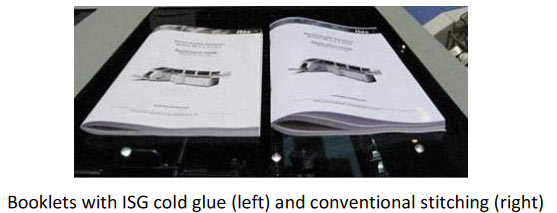

5/ Stitching or ISG cold gluing

IBIS's unique and patented ISG cold glue system provides a higher quality binding alternative to wire stitching. Some insurance companies insist on using ISG cold glue to bind their policies instead of wire stitching for the following reasons:

a) ISG cold glue binding gives improved booklet 'lay-flat', which can greatly help subsequent inserting and mailing operations because it makes it easier to insert the policy booklet into an envelope.

b) If a policy recipient removes a page from an ISG glued booklet then this is evident because the paper appears 'torn'. The recipient cannot therefore maintain that he did not receive this page in the policy. With a stitched booklet a page can be removed without this being evident.

c) The ISG glue binding process allows booklet thickness to be easily varied on-the-run from 2 sheets up to 10mm total thickness without any adjustments needed to the wire stitching process.

Videos

View the IBIS Smart-binder Introduction Video

View a video of the Smart-binder SB-3 fed from a web-cutter producing personalized insurance booklets with a variable number of pages.

Case Studies

Each of the following customers are using the IBIS Smart-binder exclusively to produce Insurance Policy Documents

Case study 1: R + V , Wiesbaden Germany

The company R+ V located in Wiesbaden Germany is part of the Cooperative Financial Network which includes more than 800 Volksbanken and Raiffeisenbanken, and other banks. Overall this group has more than 30 million customers and a balance sheet total of one trillion euros annually. R+ V is integrated into the structure and has more than 5,000 sales representatives providing insurance services throughout Germany at the institutes.

For many years R & V have used an IBIS Smart-binder (saddle glue-binder) every day to produce all the insurance policy documents needed for this group. Each document is individually personalized and the outside cover (fed from the IBIS cover feeder) has a 'window' to allow the name and address of the policy holder to show through.

![]() Mr

Thomas Wenske, Head of Printer Center for R + V says:

Mr

Thomas Wenske, Head of Printer Center for R + V says:

We acquired one of the first Smart-binder SB-3s built by IBIS in 2005 as part

of a major rebranding exercise. This included improving the face of documents

and policies to bring more worth and value for our customers. There were a

lot of steps to reach this goal and the IBIS was an important component. It

provides integrity and security through individual sheet gluing, which also

looks much better than wire stapling and provides a flatter booklet which

is easier to insert into an envelope. We are able to produce good looking

insurance policies for our customers at high speed and with high value.

The original IBIS Smart-binder worked extremely well, enabling us to increase

productivity by 30%, and further improve our ability to personalize our

insurance policy documents. Since we were confident to invest again in this

world-leading IBIS technology, we installed a further new Smart-binder in

2013 and another new Smart-binder again this summer 2022.

We are delighted to have been able to have provided R+V with our patented

IBIS 'ISG' glue binding system integrated into a heavy duty saddle-binder,

which has enabled them to meet their customer's requirements for so many

years. ![]()

Case study 2: Spain (to be added)

Case Study 3: USA

Multiple Smart-binder users throughout the USA are using IBIS Smart-binder system to produce Health Insurance Policies and Info Booklets. One customer example in Minnesota is running their Smart-binder in-line with a Canon Prostream printer : see in-line with Canon ProStream 1000 inkjet web press (ibis-bindery.com)

Other Smart-binders are used to produce different types of insurance documents. Here is a testimonial statement from Farmers Insurance in LA:

![]() Herb

Lamonda, OPC Director, states:

Herb

Lamonda, OPC Director, states:

The addition of three IBIS Smart-binder systems in-line with Océ

web printers has greatly improved our look and feel of the insurance policy

documents and the mailing of these to our customers. The change from a

side-stitched document to a professional looking 3-side trimmed saddle-stitched

booklet has significantly enhanced the professionalism of the end-product.

The booklet lay-flat from the Smart-binder greatly assists the insertion

into envelopes. The Smart-binder has also enabled us to reduce paper weight

which has resulted in a large postal cost saving to Farmers. During peak

periods the three Smart-binders are used round the clock and their robust,

heavy duty design lends itself well to our demanding performance requirements.![]()