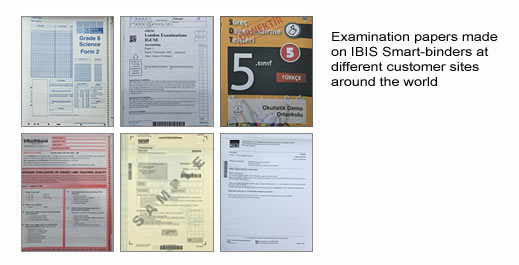

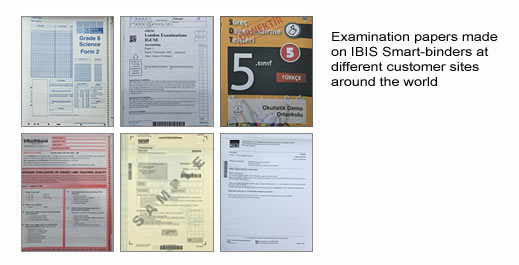

The

IBIS Smart-binder is the premium saddle-binding solution for in-line

operation with more systems installed around the world than from

any other manufacturer. In-line exam paper production is one of

the most common applications for the Smart-binder system.

More

printing companies are using IBIS Smart-binders to produce exam

papers than any other digital finishing system. The reasons for

this are as follows:

1) Booklet integrity

It is essential that no sheet ends up in the wrong exam paper. The

Smart-binder therefore has a fully integrated sheet detection and

tracking system (using the bar codes on each sheet) to ensure the

integrity of each finished paper. If there is any risk that a document’s

integrity could be compromised then it is automatically rejected

2) Tighter control of printed sheets using in-line finishing

Most exam paper producers prefer to run the Smart-binder in-line

with the digital printer to avoid piles of printed sheets (or rolls)

lying around the factory awaiting finishing. This reduces any security

risk that a printed sheet could find its way into the wrong hands.

3) High reliability with minimum maintenance

The Smart-binder is a very heavy-duty system designed to operate

24/7 in-line with a high speed digital web printer with minimum

maintenance, high reliability and maximum possible 'up-time'.

4) High speed output

The Smart-binder can run constantly at very high speeds (typically

producing around 7,000 A4 booklets/hour, making 8 – 16 exam

page papers in-line with a printer running at up to 130 metres/min

web speed).

5) Variable page extents

Run lengths for exam papers can be very low, although volumes are

often high, e.g: a Smart-binder may produce one million exam paper

booklets a month. It is therefore a key feature that the Smart-binder

can change the number of pages in each booklet ‘on-the-run’

under bar-code control, while maintaining the integrity (correct

page sequence) in each individual booklet.

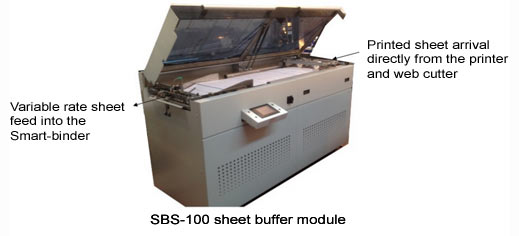

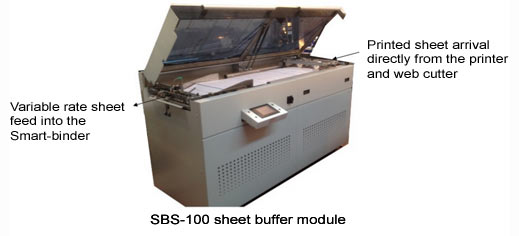

To help produce variable page extent exam papers, particularly if

some documents contain a very small number of pages (4 or 8), we

have developed a new sheet buffer module.

This

in-line buffer module stores sheets arriving from the printer and

feeds them into the Smart-binder at a rate determined by the number

of sheets in each book. It also allows the Smart-binder to stop

and restart without stopping the web printer, improving the efficiency

of the whole line.

6) Cover matching

A separately-printed cover sheet, if needed, may be fed from the

optional Smart-binder cover feeder. If personalised then the cover

may be bar coded so the Smart-binder can ensure it is correct one

for the booklet to which it is attached

7) Document personalisation

Exam papers may be personalised and may include the student’s

name. Consecutive papers may include the same questions but in a

different sequence (to reduce risk of a student copying from their

neighbour during the exam).

8) Data Tracking

The Smart-binder includes a sophisticated tracking system using

bar code (or Datamatrix) code readers and sensors. The Smart-binder

control PC retains log files containing production data relating

to each booklet produced, so rejected booklets can be reprinted.

The production log files may be viewed externally with a network

connection if required

9) Answer sheets and automated marking

The Smart-binder can produce a document which includes both the

questions and an answer sheet. The answer sheet may be fed separately

from the cover/insert sheet feeder and bound together with the other

sheets, or be loose or easily detachable. If automatic ‘marking’

of completed exam papers is required the booklet spine may be cut

off and pages fed individually though the auto-marking machine.

In other cases the answer sheet itself is removed from the booklet

for auto-marking processing.

10) Wire stitching or ISG cold gluing

IBIS’s unique and patented ISG cold glue system provides a

higher quality binding alternative to wire stitching. This results

in high booklet integrity for exam paper production as sheets cannot

be removed from the booklet without tearing the paper. The improved

booklet lay-flat this system offers also helps with subsequent inserting

and mailing operations.

View

a video HERE

of the IBIS Smart-binder system in operation, February 2015, at

the Hunkeler HID show in Luzern, including the optional sheet buffer

SBS-100.

Case

Studies

The

following customers use the Smart-binder exclusively to produce

exam test papers:

Case study 1: UK

In 2008 this customer purchased the first six IBIS Smart-binders

for exam paper production. Three were installed in-line with cut-sheet

printers and three in-line with web toner printers. Since then the

Smart-binders fed from the web printers have each produced over

60 million booklets. In 2014 this customer ordered two more Smart-binders

which were installed in-line with ink-jet web printers and in 2015

two more in-line Smart-binders were added. By July 2015 we will

have installed 10 in-line Smart-binders at this site.

Case study 2: Japan

In 2006 customer ‘TF’ ordered their first Smart-binder

systems to produce examination test papers for Japanese students.

These machines operate ‘off-line’ using high-pile sheet

feeders fed from colour-printed sheets using a loading trolley system.

From 2006–2010 IBIS installed a total of 9 Smart-binders at

this site in Tokyo, all of which are used to produce exam test papers

of variable thickness and with dynamic sheet perforation. All exam

booklets produced by TF are bound using the Smart-binder’s

unique ISG cold-glue system instead of being wire stitched. Even

booklet has separately-fed cover sheet which is personalised and

‘matched’ to the inside sheets.

Case Study 3: USA

This customer has special requirements for finishing exam papers

in-line with ink-jet web printers and use three ‘customised’

Smart-binders for this purpose.

Case Study 4: Africa

Over the last 5 years, a number of IBIS Smart-binders have been

installed at customer sites in Tanzania, Malawi, S,Africa and Zimbabwe

to produce exam papers in-line with web printers. We are increasingly

finding that such countries, which in the past have chosen to have

their exam papers produced in other countries (such as in the UK),

are now preferring to bring production home. The extra security

resulting from Digital web printing with in-line IBIS finishing

is contributing to this change.

Case study 5 : Brazil

This customer ordered a Smart-binder system to produce exam papers

from pre-printed rolls (near line solution).

Case study 6: New Zealand

The customer ordered one Smart-binder system, together with Sheet

Buffer SBS-100, cover feeder and an additional insert sheet feeder,

to produce exam papers at a customer site in Wellington, NZ. This

will operate in-line with an ink-jet web printer at up to 127 m/min

web speed.

Case Study 7: UK

In 2013 we installed two Smart-binders at this site to produce exam

papers. One operates in-line with a cut-sheet printer and the other

in-line with a high speed web printer. For this customer we developed

a special corner hole punch which is installed in the Smart-binder

trimmers.

Case Study 8: Turkey

In 2014 we installed one Smart-binder in-line with an ink-jet printer

to produce exam papers at this leading printer on the University

campus, Ankara, Turkey.

Please do contact

me to discuss your requirements and for more information.

John Cracknell, Managing Director

IBIS Bindery Systems UK

search

search