Integrated

Bindery Systems

Smart-binder Description

Features, USPs, optional modules and configurations

Saddle-stitcher and glue-binder for digitally-printed sheets

This webpage also applies to the Smart Label-binder (SLB)

Smart‑binder Brochure View Smart‑binder Specifications

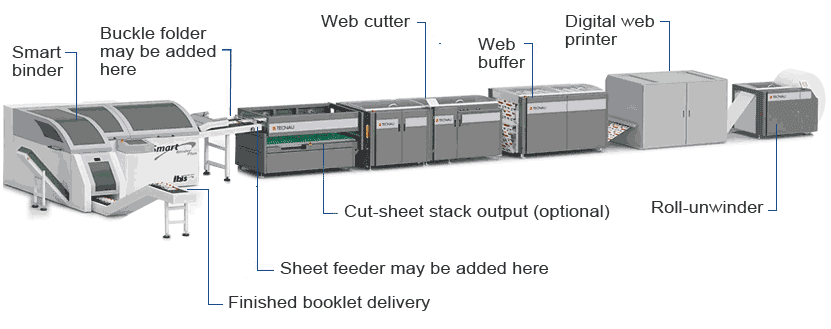

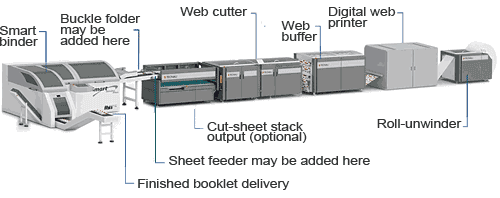

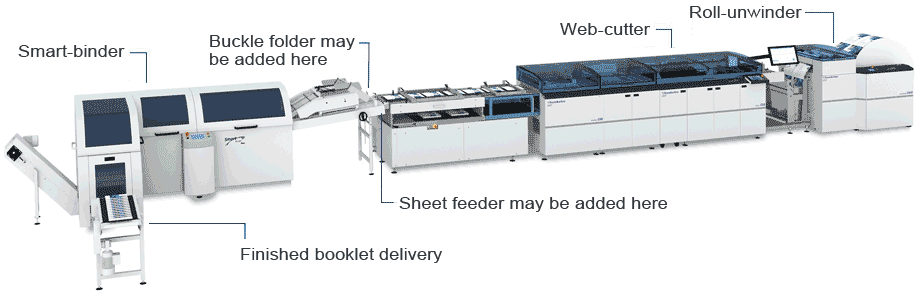

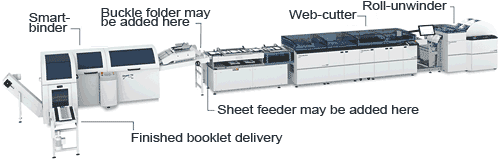

- In-line with a digital printer, or near-line from a pre-printed roll and web cutter, or off-line from a high-pile sheet feeder

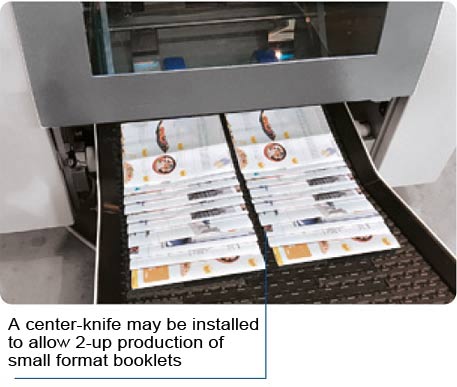

- Produce high-quality stitched (or cold glued) and 3-side trimmed booklets at up to 7,000 booklets/hour (1-up) or 14,000 booklets/hr (2-up)

- The Smart Label-binder (SLB) is a new variant of the Smart-binder that runs paper weights down to 37 gsm (without an additional folder) as required for 'Extended Content Label' (ECL) booklet production...read more

- 24/7 operation giving over 100,000 booklets/day net production output

- Number of pages in each booklet variable ‘on-the-run’

- In-built integrity checking of each booklet

Smart Label-binder, for ECL booklet production

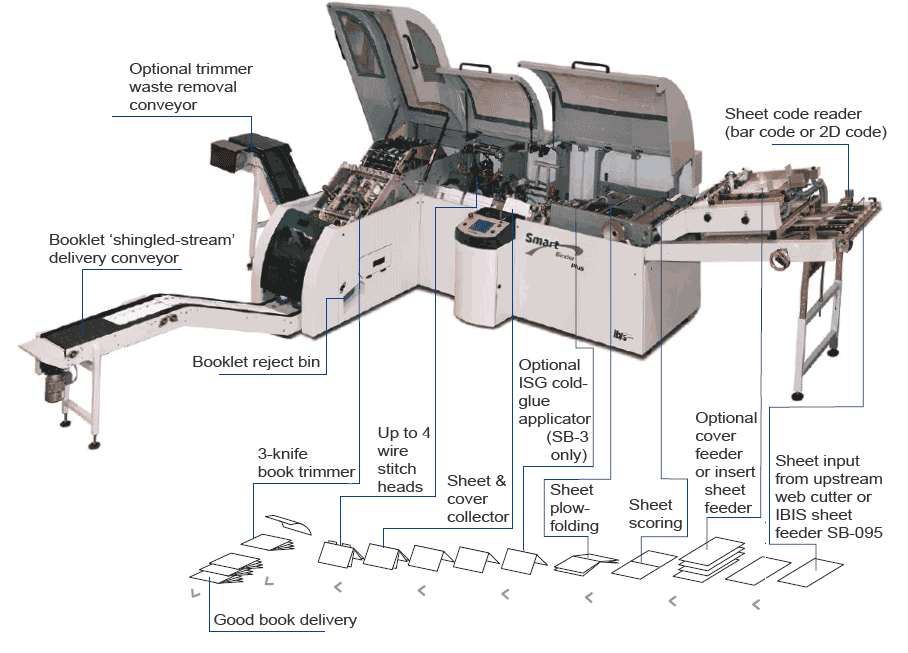

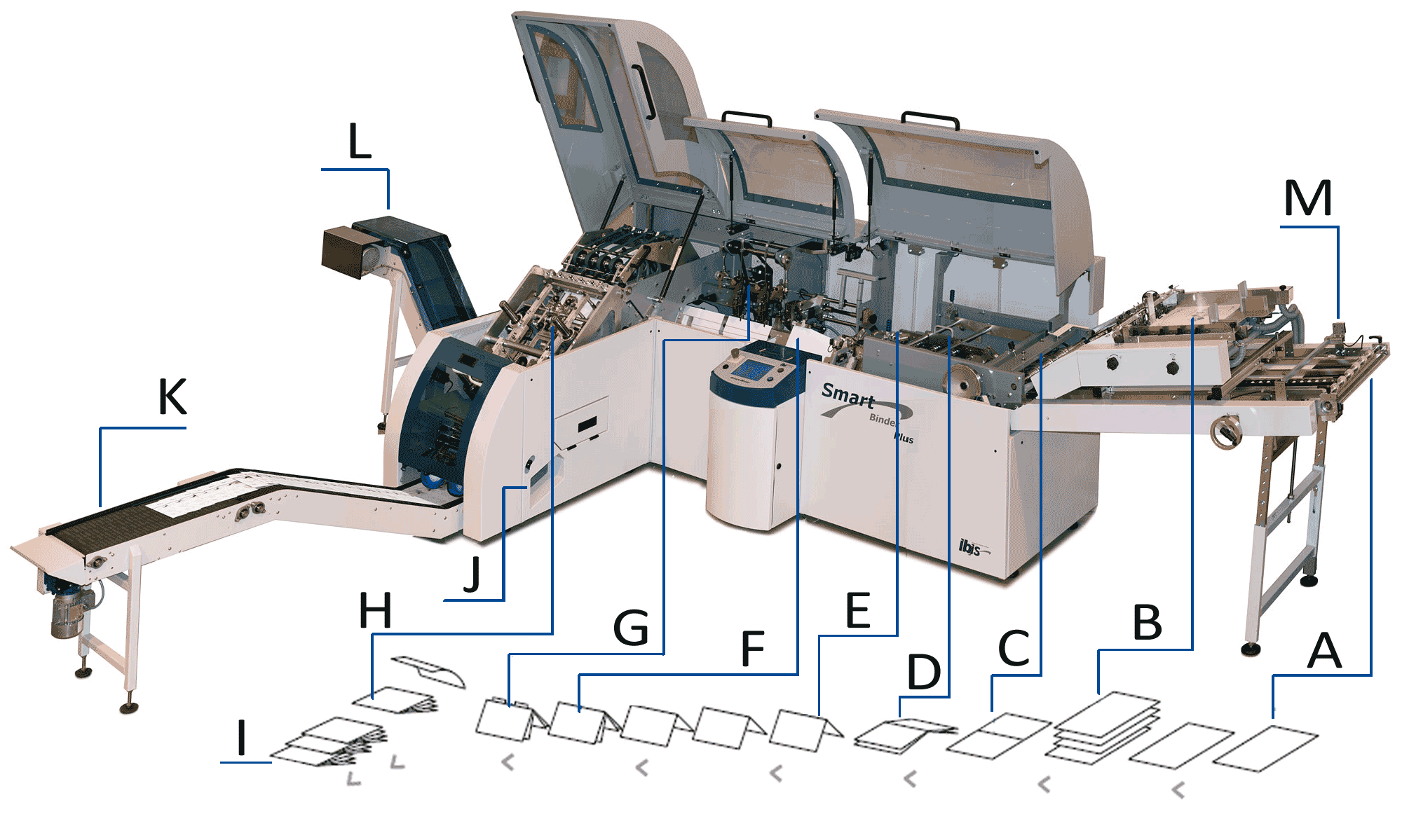

| A | Sheet input from upstream web-cutter or IBIS sheet feeder SB-095 |

| B | Optional cover feeder or insert sheet feeder |

| C | Sheet scoring |

| D | Sheet plow-folding |

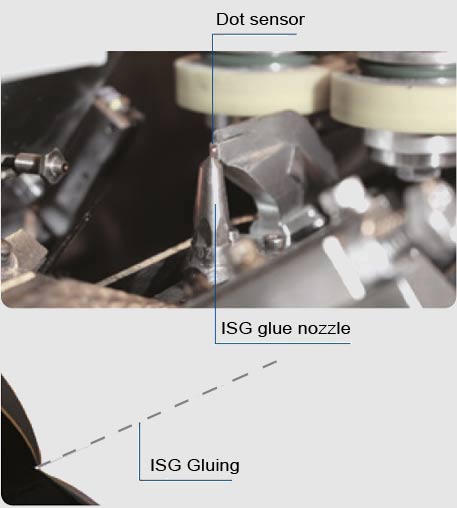

| E | Optional ISG cold glue applicator (SB-3 only) |

| F | Sheet and cover collector |

| G | Up to 4 wire stitch heads |

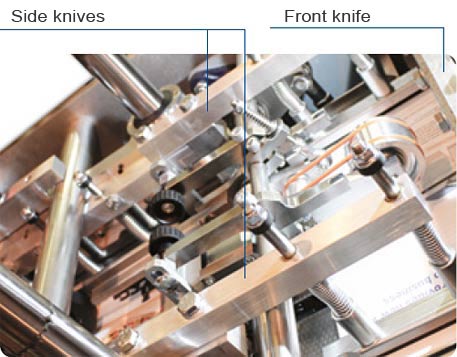

| H | 3-knife book trimmer |

| I | Good book delivery |

| J | Booklet reject bin |

| K | Booklet 'shingled-stream' delivery conveyor |

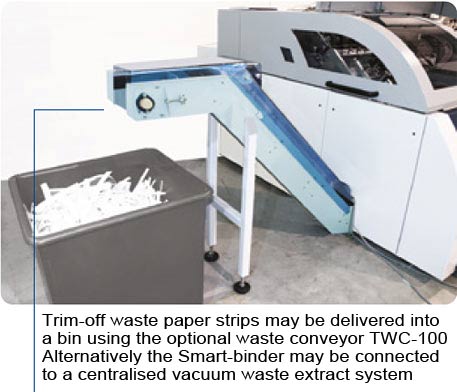

| L | Optional trimmer waste removal conveyor |

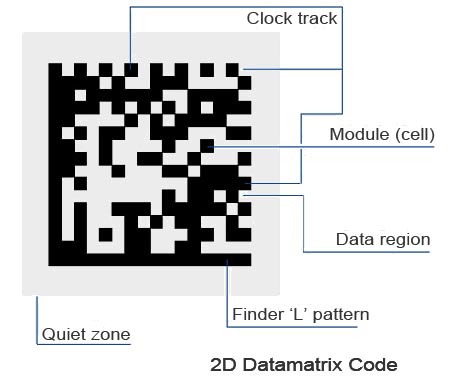

| M | Sheet code reader (bar code or 2D code) |

The Smart-binder receives printed sheets (or folded signatures) at rates up to 450 sheets/min and can produce up to 7,000 high quality stitched and trimmed booklets/hour (14,000 booklets/hour if using the optional trimmer center-knife).

The Smart-binder SB-2 provides wire stitching only of booklets up to 10mm thick. The sheets are side registered, center-scored, ‘plow-folded’ onto the Smart-binder saddle and collected together. After wire stitching each booklet is 3-side trimmed before being delivered on a conveyor in a shingled stream.

The Smart-binder SB-3 includes the option of ISG cold-glue binding as an alternative to wire stitching.

A code printed on each sheet is read on the Smartbinder infeed. The numerical data in this code enables the Smart-binder to track each sheet into correctly assembled booklets and automatically perform other functions such as selective stitching/gluing and selective perforation.

Smart-binder Features

Features & USPs

24/7 Production System for maximum ‘up-time’

- Over 190 Smart-binder systems installed world-wide

- 24/7, reliable, heavy-duty production system

- Most commonly used finishing system for high-speed digital web printers

- Continuous 3-shift 24/7 operation over many years

- Over a million booklets every month

- Outperforms other systems in its class

Integrated Sheet and Book Tracking to ensure book integrity

- Sophisticated data tracking for personalized booklets

- Integrated system of sensors and software for 100% accurate tracking of each sheet

- Incomplete booklets are automatically rejected

- Separately fed covers may be checked to ensure matching with inside sheets

- Detailed ‘log file’ provides data on individual booklets and can be used to reprint missing booklets

Book Quality

- Each sheet folded individually (competitive systems fold multiple sheets together)

- Optimum book fold quality and lay-flat

- Three-side trim for high quality finish

- Unique clamp device to minimize book spine corner tearing when making books up to 10mm thick

Bind-on-demand for book personalization, or short job runs

- Unique ability to vary book thickness on-the-run without adjustments

- Trimmer uses gravity-registration to process books with a variable thickness

- Integrated sheet and book tracking makes the Smart-binder a true ‘bind-on-demand’ system

Accurate Cover-To-Text Matching

- Optional code reader on the cover feeder

- Integrated software for personalized cover-to-book matching

Multiple Configurations

- Greatest variety of possible system configurations

- The SB-2 produces wire-stitched booklets only

- SB-3 also provides ISG cold gluing

- May be configured to operate either in-line with the printer, near-line from a roll unwinder and sheeter, or off-line from a sheet pile feeder

- Possible to operate both in-line and off-line with quick changeover

Enhanced Production Speeds give more booklets each shift

- Up to 7,000 booklets per hour (14,000 in 2-up mode)

- Web speeds up to 130 meters/min (426 feet/min)

- 180 meters/min (590 feet/min) with an extra in-line buckle-folder

Unique ISG cold-glue binding for enhanced book quality

- IBIS unique and patented ISG cold glue binding option

- Cold-glued books are stronger and lay flatter than wire-stapled books

- Automated changeover between stapling and gluing

Extended model Smart-binder –X, –W and –XW

- Extended SB-X model increases the maximum spine length from 320mm (12.6”) up to 457mm (18”)

- Can produce A5 portrait booklets in 2-up mode at 11,000 booklets/hour

- Wider version SB-W model increases max book width from 230mm (9”) up to 273mm (10.75”) ‘spine to foredge’ dimension

Customization to give you competitive advantage

- Smart-binder system customization available for large variety of applications

- Connect to envelope inserters, stackers, folders, in-line booklet drills, knife folders and numerous other options

- Additional sheet pile feeders, cover and insert feeders, in-line cover gate-folding, pile loading trolleys, trimmer center-knife, card and reply envelope tipping, dynamic sheet perforation, hole punching and much more

Ease of use and maintenance

- Easy to operate

- Good access and visibility

- Easy and economical to maintain

Compact Footprint

- Very compact overall system footprint

Cover feeding

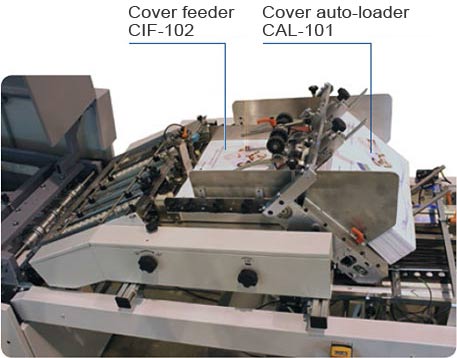

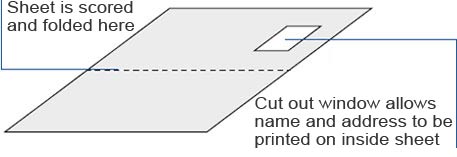

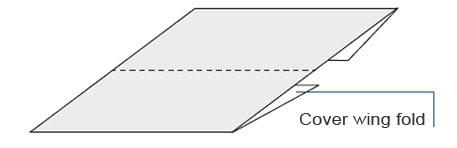

The optional Cover Feeder CIF-102 automatically feeds a cover sheet on top of the last sheet of each booklet. An ‘Insert’ sheet may also be fed at any position inside the booklet.

An optional code reader may be used to check that covers or inserts ‘match’ the other sheets in each booklet using a coded ID number printed on both the inside sheets and the covers.

The Cover Feeder may be fitted with an optional Auto-loader CAL-101 which increases the maximum cover pile height from 20mm to 200mm. An additional cover or insert sheet feeder CIF-101 is available in case both a cover and an Insert sheet feeder is needed, or two cover feeders are needed.

Collection of Sheets and Covers

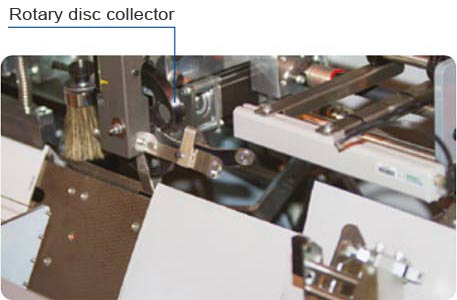

A rotary disc collect sheets in groups and then drops these onto the saddle.

This system allows the last sheet (or cover) of the book to be closely followed by the first sheet of the next book, which avoids the need for the printer or web cutter to pause when running in-line.

Wire-stitching

Up to 6 Hohner wire-stitch heads may be fitted.

The optional stop-stitch system SDI-100 deactivates the stitching process automatically under bar code control, when not needed.

Optional loop stitching (Omega/Ringoesen) is available instead of normal flat stitching.

High-quality binding option using ISG (cold-glue binding)

An optional cold glue applicator nozzle applies a row of glue dots to the inside fold of each sheet and cover (models SB-3 and 4 only) as part of the folding process.

This unique cold glue binding option ISG-100 provides a higher quality alternative to conventional wire stapling and is a patented IBIS solution. A light sensor detects each dot of cold glue and stops the Smart-binder immediately if the nozzle is blocked to ensure only correctly bound booklets are produced. After gluing, the sheet and cover are pressed together to ensure a high quality bind.

ISG cold glue binding offers a stronger bind, better booklet lay-flat, and an easier-to-use alternative to conventional wire stapling. The SB-3 can switch automatically on-the-run between wire stitching and ISG cold gluing, under bar code control.

Book trimming

The Smart-binder is normally supplied with a heavy-duty 3-knife book trimmer, capable of cutting books up to 10mm thick. Alternatively just a single (front knife) trimmer, or no trimmer, may be used.

The unique book transport system allows book thickness to be continually changed without having to stop the machine for manual adjustments.

An optional special spine clamping system may be used to eliminate book spine corner ‘tearing’ when making thick booklets.

Book delivery

Booklets are delivered in a ‘shingled stream’ on the delivery conveyor.

Gaps may be created automatically in the stream to create a pre-determined number of booklets in each batch. Alternatively booklets may be delivered into downstream modules such as the ink-jet printer to personalise the outside cover, sheet inserter, booklet stacker, pile bander, pile poly-wrapper and pile-labeller. These additional downstream modules are often required for high-security applications such as examination booklet production.

Optional booklet stacker

The optional stacker BSS-10 may be connected in-line to the Smart-binder delivery to produce ‘compensated’ piles of booklets up to 330mm high. This provides ‘operator-free’ system operation for long periods.

The BSS-10 stacker can be fitted with code detection and additional software to allow 'intelligent stacking' if needed (for example each stack may contain booklets for a specific classroom)

Booklet quality control, personalised booklet production and smart-data Analysis

A bar code or 2D reader reads a code printed on each sheet. The Smart-binder then tracks each sheet through to complete booklets.

The number of sheets may vary from one booklet to the next to allow personalised booklets. An automatic reject gate diverts any ‘incorrectly assembled’ booklets into a reject bin. Booklets are rejected if the page sequence is not correct (or if there is a risk it could not be correct), or if they are not of the required quality.

Data is available to allow rejected books to be automatically re-printed. Read more about Smart-binder booklet integrity and control.

The optional SDA-100 Smart-data Analysis System displays all Smart-binder performance data recorded over selected time periods and may be linked to combine data from multiple machines.

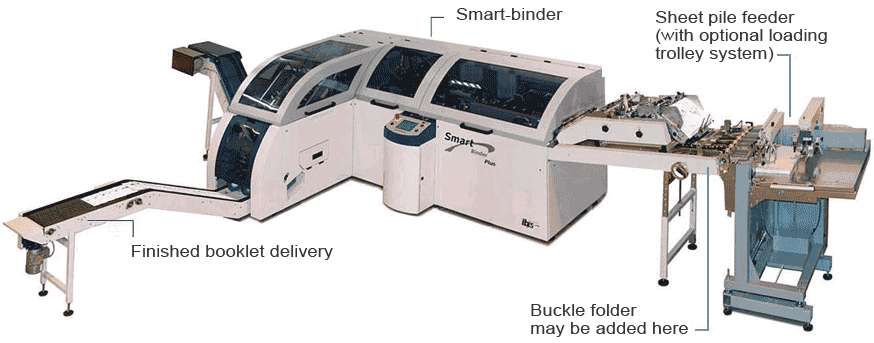

Feeding the Smart-binder from a sheet feeder (off-line)

Two different high-pile sheet feeders are available. These may be loaded with up to about 7,000 printed and coded sheets.

Feeder version SB-095 is used if the system is to be always fed off-line from the sheet feeder. Feeder version SB-097 allows feed from an upstream web cutter (near line or in-line operation) in addition to off-line feed from a sheet pile. The SB-095 feeder may be provided with an optional loading trolley PLT-100 or HPL-100 (SB-097 may be provided with HPL-100) to reduce pile reload time to about 35 secs.

Sheet perforation

The optional sheet perforation module DMP-100 or DMP-101 perforates each sheet on demand under automatic bar code control.

Up to 4 lines of perforation may be applied to each sheet, parallel to the booklet spine, to allow, for example sheet tear-out.

Sheet folding and rotation

The optional sheet folder sheet folder F-100 may be used to buckle-fold each sheet prior to entering the Smart-binder infeed conveyor.

This allows small format booklets to be produced from a large format sheet containing 8 or more pages. Use of the buckle-folder (without sheet rotation) also allows the minimum paper stock weight to be reduced, or allows maximum web speed to be increased from 130 metres/min up to about 150 metres/min or faster.

The sheet rotator/folder SRF-100 may be positioned so sheets flow into the SR-100 rotator where they are rotated 90 degrees, then feed into the F-100 folder. This enables small format booklets such as A5 or 5 ½ x 8 ½” to be produced from a web width of 450mm or 18”, and avoids having to change to a ‘narrow’ web.

Smart-binder Videos

Smart-binder Performance Table

Swipe columns to left to view all the table.

| Number of SRA3 sheets& A4 pages (in brackets) in booklet (excluding separately-fed cover sheet) | Web speed (meters/min) 100 m/min=328 feet/min) |

Output rate (books or sigs/min @ 100% efficiency) |

Output rate (books or sigs/min @ 90% efficiency) |

|---|---|---|---|

| 2 (8) | 61 | 100 | 90 |

| 3 (12) | 92 | 100 | 90 |

| 4 (16) | 100 | 81.4 | 73.3 |

| 8 (32) | 100 | 54.3 | 48.9 |

| 12 (48) | 100 | 27.1 | 24.4 |

| 16 (64) | 100 | 20.4 | 18.3 |

| 24 (96) | 100 | 13.6 | 12.2 |

| 32 (128) | 100 | 10.2 | 9.2 |

| 40 (160) | 100 | 8.1 | 7.3 |

| 50 (200) | 100 | 6.5 | 5.9 |

Top

Smart-binder Configurations

In-line Smart-binder

Fed directly from digital printer and web cutter

Near-line Smart-binder

Fed directly from roll-unwinder and web cutter

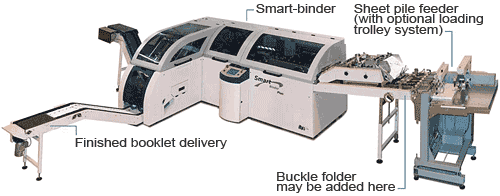

Off-line Smart-binder

Fed directly from sheet pile feeder

Top

Smart-binder & SLB Optional Modules Flow Chart

|

Smart-binder (saddle-stitcher) & SLB  |

|

In-line Smart-binder & SLB  |

|

Near-line Smart-binder & SLB  |

|

Off-line Smart-binder & SLB  |

|

Modules downstream from Smart-binder or SLB  |

Market Segments served by the Smart-binder

The Smart-binder is ideal for all short-run or time-critical printing

Most common Smart-binder applications

- Healthcare and medical insurance

- Other insurance documents

- Exam papers

- Product manuals

- Legal and Financial documents

- Government papers

- Church bulletins

- Music books, Pharmaceutical booklets, short run magazines, etc.

Smart-binder Customer Feedback from around the World

O’Neil Data Inc., USA

Steve Ellithorpe, Operations Manager, O’Neil Data Systems, Los Angeles, states:

“We have built up years of experience in running four IBIS Smart-binders at our production site in LA. These machines proved to be solid performers and capable of operating at peak production rates over a long time periods. Our first thought, therefore, when setting up a new O’Neil facility in Plano, Texas was to look to IBIS for additional finishing equipment. We recently installed additional Smart-binder systems in Plano which are now operational and contributing well to this large new production site. We are pleased to have become one of the largest users of IBIS Smartbinders in the USA.”

AMF Impresion Variable S, Chile

AMF purchased an IBIS Smart-binder SB-3 fed from a high pile sheet feeder to product examination booklets.

AMF’s Operations manager, Rodrigo Santelices:

“Our new off-line IBIS Smart-binder system is fed with piles of printed 4pp sheets which it feeds at high speeds. It produces for us high quality stitched and 3-side trimmed 8 ½ x 11” examination booklets containing a variable number of pages. We also have the option of IBIS’s patented ISG cold glue binding system on this machine. This provides a unique new alternative to conventional wire stitching. The Smartbinder is a very heavy-duty and reliable system that is already performing well for us.”

O’Neil Data Inc., USA

Steve Ellithorpe, Operations Manager, O’Neil Data Systems, Los Angeles, states:

“We have built up years of experience in running four IBIS Smart-binders at our production site in LA. These machines proved to be solid performers and capable of operating at peak production rates over a long time periods. Our first thought, therefore, when setting up a new O’Neil facility in Plano, Texas was to look to IBIS for additional finishing equipment. We recently installed additional Smart-binder systems in Plano which are now operational and contributing well to this large new production site. We are pleased to have become one of the largest users of IBIS Smartbinders in the USA.”

Esser printSolutions, Germany

Markus Esser, Esser printSolutions GmbH, Karlsruhe, Germany:

“We are constantly searching for new

possibilities which our customers can profit from. One example is the manufacture of handbooks, brochures and product operation manuals with variable “On Demand” content. The first IBIS saddlestitcher (Digi-stitcher) system was installed at Esser PS 13 years ago and was replaced with a Smart-binder about 9 years ago. These machines enabled us to fulfil our requirements in the optimum way. We have been pleased with the Smart-binder performance. To expand our digital finishing capabilities IBIS have now installed an additional IBIS Smart-binder, the latest model ‘Plus HS’, which is fed from a Hunkeler unwinder, web cutter and MBO folder at web speeds up to 180 meters/min”.

Maqprint, France

In their print factory close to Limoges, France Maqprint use a unique system using a Smartbinder to produce stitched and trimmed booklets from rolls printed on an HP web printer.

Philippe Sans (owner of Maqprint):

“When we explained to IBIS what we needed, they constructed a customized finishing system for us. The system runs very reliably and is a key component in enabling us to meet our customer’s requirements.”

Commitment Statement

IBIS is committed to offering our customers the highest quality digital finishing solutions and we will always:

- Act with openness and integrity in all our dealings with you, respond within one working day and respect the confidentiality of information you give us

- Only sell to you if we are confident that we can satisfy your requirements

- Review how our equipment may be customized to suit your specific needs

- Test and demonstrate your finishing job prior to sale, if needed

- Continue to work with you after installation until we achieve pre-agreed system performance

- Give you continued technical support in the future

I look forward personally to helping you put into operation a complete and highly-effective book-finishing system which will increase your competitiveness and grow your business.

For further information, don’t hesitate to call me.

Phone: +44 1494 561 950, E-mail: John.Cracknell@ibis-bindery.com

John Cracknell

Managing Director, IBIS Bindery Systems

Our reseller and support partners include

Contact Us

IBIS UK (Head Office)

| Contact | John cracknell (Sales) Martin Reed (Customer support) |

| Phone | +44 1494 561 950 |

| Fax | +44 1494 561 951 |

| Address | 9, The Gateway Centre, High Wycombe HP12 3SU, UK |

| sales@ibis-bindery.com |

BEST GRAPHICS GROUP (USA Distributor)

| Contact | Mark Spelman |

| Phone | 800 236 7603 |

| Address | W17 W24340 Riverwood Drive, Waukesha WI 53188, USA |

| danb@bestgraphics.com |