The Smart-binder may be supplied as model SB-3 which also includes IBIS’s unique ISG cold-glue binding system.

The Smart Label-binder, used to produce ECL booklets, normally uses ISG cold-glue binding when making Pharma ECLs but may use either ISG gluing or conventional wire stitching when making other types of ECLs, such as Agro-Chem.

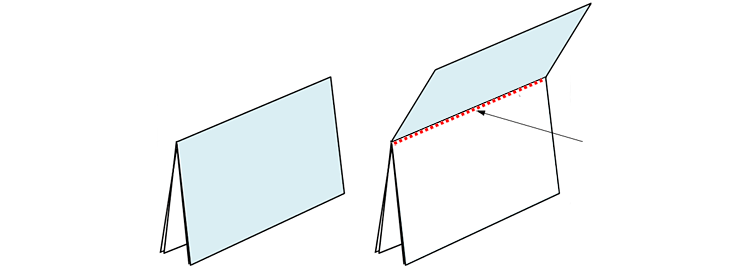

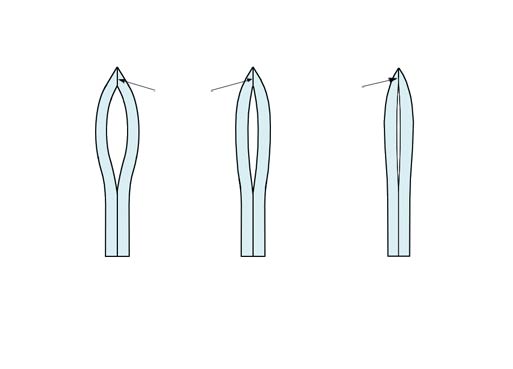

ISG cold-glue binding produces a “stitchless” book which has better lay-flat qualities than a wire-stitched booklet, as illustrated in the photo below. The lay-flat difference is less pronounced when making thin booklets.

The ISG cold-glue ‘nozzle’ applies a row of cold-glue ‘dots’ (or a continuous glue line) to the inside of each folded sheet as it passes through the Smart-binder folder. A light sensor detects each dot of cold-glue and stops the Smart-binder immediately if the nozzle is blocked to ensure only correctly bound booklets are produced. Sheets are then collected on top of each other (on the saddle) and pressed together tightly when they reach the stitching station (the stitching heads are inhibited when cold-gluing, or replaced with a pressing ‘anvil’).

The many advantages of ISG cold-gluing over conventional wire-stapling include:

For the recommended glue to be used with the ISG-100 system view the ISG glue: info & specs datasheet. If an alternative glue is used then it must have a similar specification.