Integrated

Bindery Systems

Exam Booklet Production

Using the IBIS Smart-binder

Exam booklet production PDF data sheet View case studies

The Smart-binder is the premium saddle-binding solution for production of examination booklets from digital printed sheets:

View Videos: Smart‑binder (SB) producing exam papers SB producing exam papers, Dubai 2025

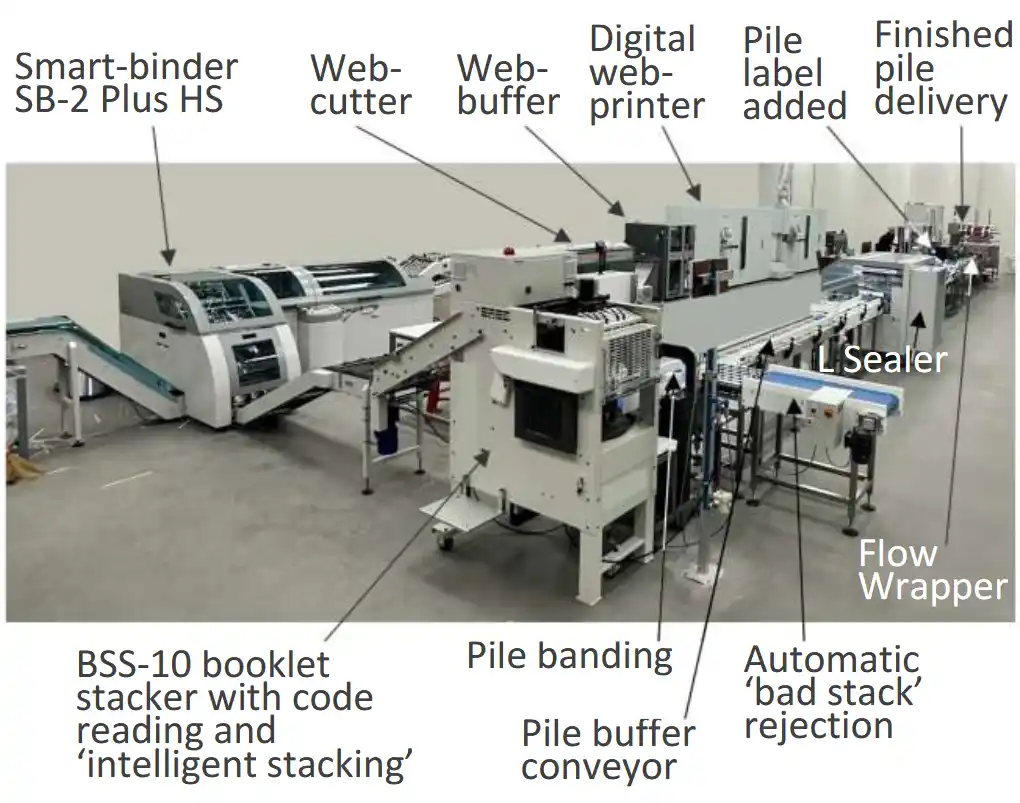

TYPICAL EXAM BOOKLET PRODUCTION LINES

WHY USE THE IBIS SMART-BINDER

More printing companies are using IBIS Smart-binders to produce exam booklets compared with any other digital finishing system. The reasons for this are as follows:

1. Booklet security and integrity

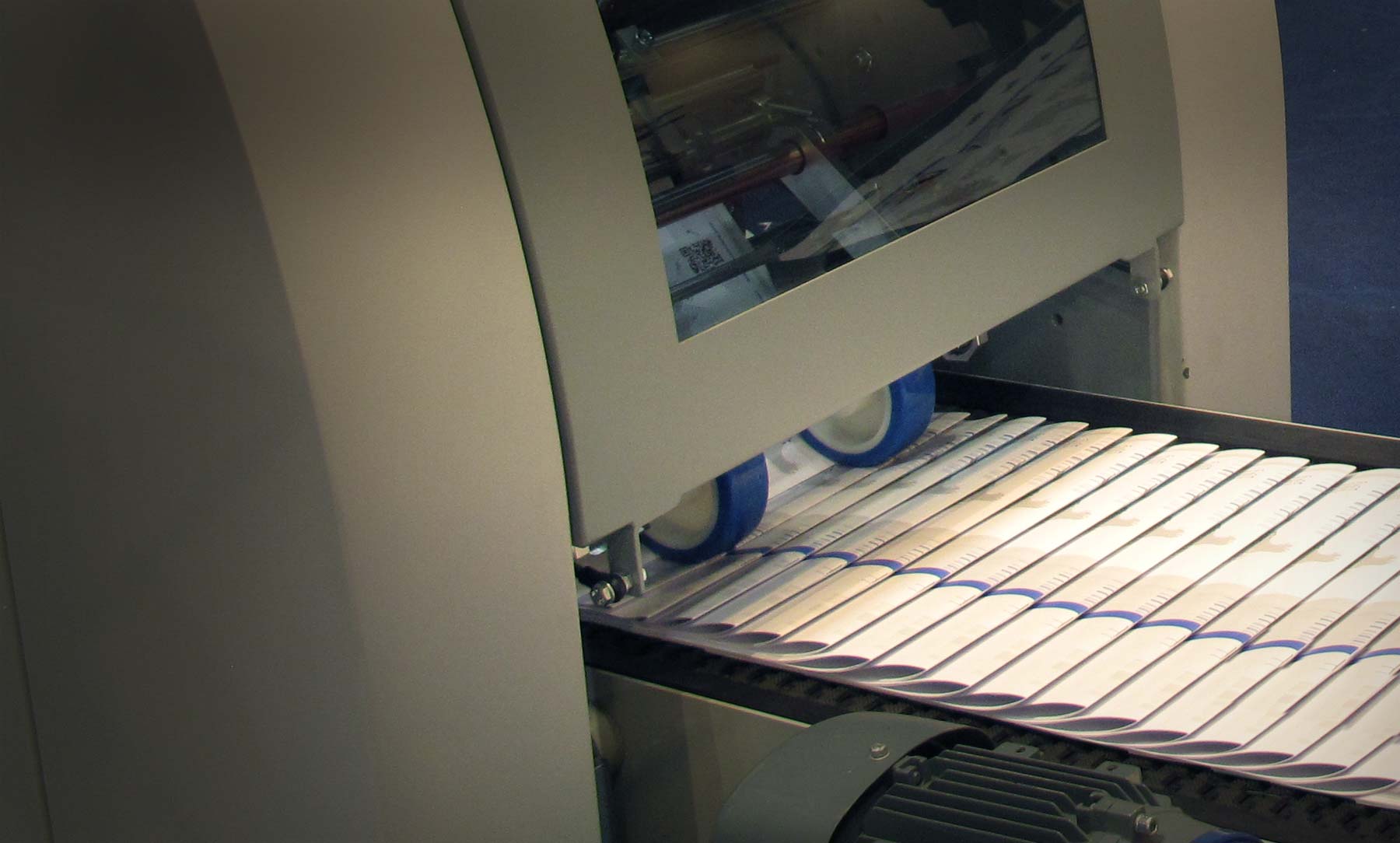

The highest priorities for exam booklet production are security and page integrity. Security is needed to ensure that there is no breach of printed examination booklet data. Finishing in-line with the printer is often preferred because then printed sheets or rolls do not need to be stored prior to stitching: they are finished directly into booklets. Finished booklets are often immediately stacked, strapped and/or wrapped so that the printed data cannot be viewed by anyone until the pile bundles are unwrapped in the examination test location.

It is essential that no sheet can mistakenly end up in the wrong examination booklet resulting in one student with a page missing and another with an additional incorrect page - not the best start for a successful exam result for those individuals!

For this reason the Smart-binder has a fully integrated sheet detection and tracking system (using a bar code printed on each sheet) to ensure the integrity of each finished booklet. If there is any risk that a booklet could have incorrect pages, or the correct pages in the wrong sequence, then it is automatically rejected.

Examples of examination booklets made by IBIS Smart-binders at different customer sites around the world.

2. High reliability with minimum maintenance

Machine 'availability' (up-time) is important in a high volume exam booklet production environment, particularly when operating in-line with a digital web printer. The Smart-binder is a very heavy-duty system designed to operate 24/7 with the minimum of maintenance and with the highest possibility reliability. Some IBIS Smart-binders have produced over 70 million examination booklets.

3. High speed output

Exam booklets normally contain a small number of pages which means a high cycling rate if running inline with a high speed digital printer. The Smart-binder can therefore run constantly at web speeds around 100- 150 meters/minute and typically producing around 7,000 A4 booklets/hour when making 8 - 16 page booklets

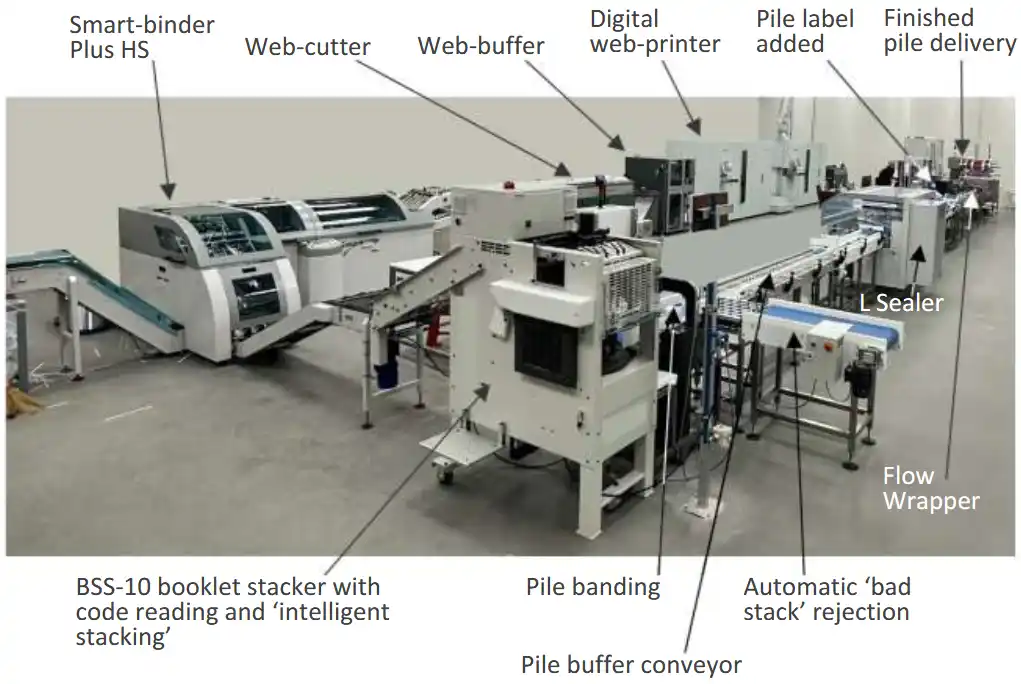

4. Stacking, strapping, wrapping and labelling

The optional Booklet Stacker BSS-10 is often used when making examination booklets when they contain a small number of pages because of the resulting high production and also because it is desirable to reduce the number of operator contact points and the number of opportunities for the printed data to be visible.

BSS-10 book stacker

For this latter reason the stacked booklet piles are often then immediately

in-line strapped (to avoid the booklets being removed and opened) and

also sometimes fully wrapped. Printed labels may need to be added at this

stage to identify the school and/or the specific exam for which the booklet

stack is intended.

5. Variable page extents

Sometimes the run lengths for exam booklets can be very low, even though the daily volumes can be very high. e.g. 1 million exam booklets a month from each Smart-binder. The Smart-binder can change the number of pages 'on-the-run' under bar-code control, while maintaining the integrity in each individual booklet (correct pages in the correct sequence).

6. Cover matching

A separately-printed cover sheet, if needed, may be fed from the optional Smart-binder cover feeder. If personalized then the cover may be bar coded so the Smart-binder can ensure it is correct one for the booklet to which it is attached (note: examination booklets do not normally require a separately fed outside cover sheet).

7. Document personalization, question shuffling and booklet tracking/reprint

Exam booklets may be personalized and may include the student's name. Consecutive booklets may include the same questions but in a different sequence to reduce risk of the student copying from their neighbor during the exam process. This is sometimes called 'question shuffling'.

Data tracking is often essential in order to know exactly which exam booklets have been produced and to allow any missing/rejected booklets to be reprinted. The Smart-binder includes a sophisticated tracking system using Bar code (or Datamatrix) code readers and sensors. The Smart-binder control PC retains log files containing production data relating to each booklet that has been produced or rejected. The production log files may be viewed externally with a network connection if required. The optional SDA-100 Smart-Data Analysis system assists with the upstream interface to enable automatic reprinting of any missing booklets

8. Answer sheets and automated marking

Exam question booklets may sometimes need to include an 'answer sheet' on which the student provides an answer to each question during the exam. The Smart-binder can produce a booklet which contains both the questions and the answer sheet. The answer sheet may be printed together with the question sheets in which case it may receive a line of perforation from the option DMP-100 dynamic perforator to allow it to be easily detached from the question booklet.

removed

Perforated Answer Sheet

Alternatively, the answer sheet may be separately printed and loose -inserted into the finished question booklet . Automatic 'matching' is then provided to ensure that each booklet contains the correct answer sheet

Automatic 'marking' of completed 'multiple choice' examinations may require the spine of the booklet to be slit off so that the pages can then be fed individually thought an automatic marking machine. Alternatively it may be the completed multiple-choice answer sheet itself which is removed from the booklet for processing by the marking machine.

9. Wire stitching or ISG cold gluing

IBIS's unique and patented ISG Cold Glue system provides a higher quality

binding alternative to wire stitching. This results in improved booklet

lay-flat which can help subsequent inserting and mailing operations.

delivery (to optional

BSS stacker)

sheet

entry

IBIS Smart-binder 'Plus HS

View the IBIS Smart-binder system in operation on our website.

View a video of the Smart-binder SB-2 producing 16pp A4 exam booklets in-line with Canon Colorstream 6000 series printer at 100 metres/min web.

IBIS-MML IN-LINE WRAPPING SOLUTIONS FOR SECURE EXAM BOOKLET PRODUCTION

The IBIS-MML partnership specializes in providing customized in-line booklet wrapping solutions to ensure the highest possible security for examination test booklet production

For more information on Exam Booklet Wrapping please follow the links below.

Case Studies

View Case Studies of customers that are using the IBIS Smart-binder exclusively to produce exam booklets: