Integrated

Bindery Systems

Smart Label-binder

For 'Extended Content Label' (ECL) booklets production

with optional laser-tabbing

The Smart Label-binder (SLB) is a special variant of the standard Smart-binder.

With high-quality cold-glue spine binding it has been optimised for the production of 'Extended Content Labels' (ECLs) when used together with an in-line laser-tabbing machine. It offers integrity, speed, and quality with maximum efficiency and reliability. The SLB can run paper weights as light as 37gsm without requiring the folder F-100.

Why choose the IBIS Smart Label-binder

The IBIS Smart Label-binder (SLB) provides unmatched flexibility and performance for ECL production, ensuring that every booklet is produced at the highest quality – first time, every time.

Feeding options

- Off-line feed from a high-pile sheet-feeder at feed rates up to 6 sheets per second

- Near-line feed from a roll-unwinder and web-cutter at web speeds up to 180 meters/min

- In-line feed from a digital web-printer and web-cutter, or a digital cut-sheet printer

- Combination of feed from a web-cutter or feed from a sheet pile, with quick changeover between each mode.

fed off‑line from a sheet feeder

fed near‑line from a web‑cutter

Key benefits

- Eliminates the multiple manual operations normally associated with conventional ECL production

- Label booklets containing a variable number of pages: up to 200, or more

- Patented ISG cold-glue binding: Stronger, flatter booklets that integrate seamlessly into packaging

- High-speed production: Up to 7,000 cycles per hour (42,000 ECL booklets/hour if running 6-up)

- 100% production integrity: Sheet-level tracking and error rejection to eliminate waste

- Flexible configurations: Inline, near-line, or off-line to suit existing print workflows

- In-line laser cutting of the outside cover for extended tabs needed for Pharma ECLs

Applications

- Pharmaceutical and healthcare

- Agrochemical

- Industrial products

- Consumer goods packaging

ISG glue binding with missing glue detection

Patented ISG‑cold glue binding, ideal for ECLs where wire stitching isn’t suitable. Optical sensor monitors glue application. Automatic System stop if any glue drop is missing.

Integrity, Tracking and Reporting

Every sheet is code-read and tracked throughout production. Automatic rejection of incomplete or incorrect booklets. Individual booklet status data for full audit and quality control. Ensures 100% booklet integrity.

Maximum flexibility

The modular design of the SLB allows you to tailor the system to your exact requirements. Options such as automated cover feeders, autoloaders, dynamic perforation, and integrated data management tools make the SLB the most versatile ECL booklet solution on the market.

Light weight paper

Most ECL label booklets must be produced using very lightweight paper stock in order to contain as much printed data as possible with the minimum number of pages.

The SLB can handle paper stocks as light as 37gsm (reduced feed speed) or 45 gsm (full speed).

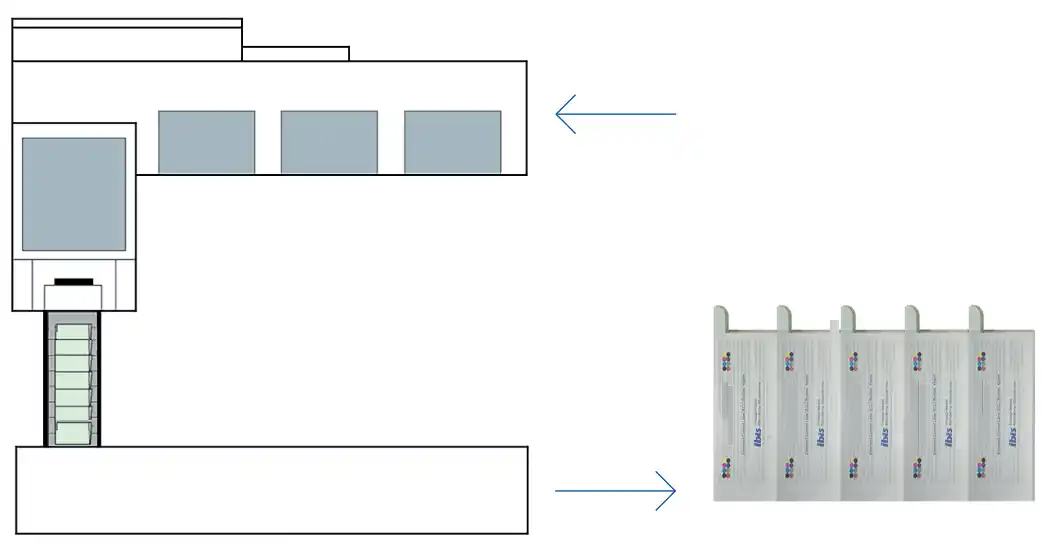

Multi-up production

The SLB produces booklets with spine lengths up to 320mm. Typically this means that multiple small format ECLs are produced in one booklet and these are separated at a later stage in the process. This multi-up process combined with quick job changeovers results in exceptionally high production efficiencies.

Laser cutting for extended tabs

The additional Laser-Tabber model LT-101 brings a new level of efficiency to Pharma ECL production. Designed to work in-line with the IBIS SLB, the LT-101 provides a clean, efficient and flexible tabbing solution:

- Precise laser cutting of the outside sheet for consistent, high quality extended tabs

- Booklet trimming to reduce the width of all other sheets

- Increased production speed, quick job changeover time and reduced waste

- Seamless in-line integration with the Smart Label-binder

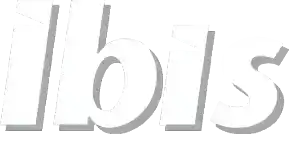

SLB with Laser‑Tabber LT‑101 (floor plan)

The ultimate solution for Pharma ECL production

The IBIS Smart Label-binder with optional in-line LT‑101 Laser‑Tabber helps you achieve faster, high-quality, and more reliable ECL production – whether you’re scaling up or optimizing your current processes.

The Laser-Tabber automatically opens up the front cover, laser-cuts the front edge of the cover to create the required extended 'tabs' and cuts all the other pages to a shorter width so that only the 'tabs' remain extending on the front edge of the booklet

with extended tabs

SLB Specifications Video: SLB at HID 2025 Video: SLB producing ECL labels

The following webpages also apply to the SLB: Smart‑binder description Smart‑binder intro video Additional equipment

For more information about the Smart Label-binder and the LT-101 Laser‑Tabber contact IBIS.