Integrated

Bindery Systems

Introduction from John Cracknell, IBIS Managing Director

![]() Digital printing continues to grow at the expense of traditional offset

printing and we are proud to be part of this growth. However,

the full benefits of digital printing cannot be realized without

suitable ‘print finishing’. The IBIS team are experts

in addressing these needs and specialize in the integration of

high-speed finishing systems with continuous-web digital printers.

Digital printing continues to grow at the expense of traditional offset

printing and we are proud to be part of this growth. However,

the full benefits of digital printing cannot be realized without

suitable ‘print finishing’. The IBIS team are experts

in addressing these needs and specialize in the integration of

high-speed finishing systems with continuous-web digital printers.

Since the year 2000 when we introduced the first in-line digital saddle-stitcher, our IBIS products have been used for a wide range of different jobs, including production of booklets for examinations, health care, financial services, insurance, government printing, manuals and many other applications. These booklets may be individually personalized, often have to be produced in very short time windows and require 100% integrity control.

Our flagship products, the IBIS Smart-binder and Smart Label-binder systems are fast, reliable, durable, easy-to-maintain and contains many innovative design features such as the option of ISG cold-glue binding in place of conventional wire-stitching, and many other USPs to give you competitive advantage. It may be used in-line with the highest speed printers, or near-line/off-line. We also excel in integrating diverse modules from other manufacturers to create specialized systems with unique and customized features.

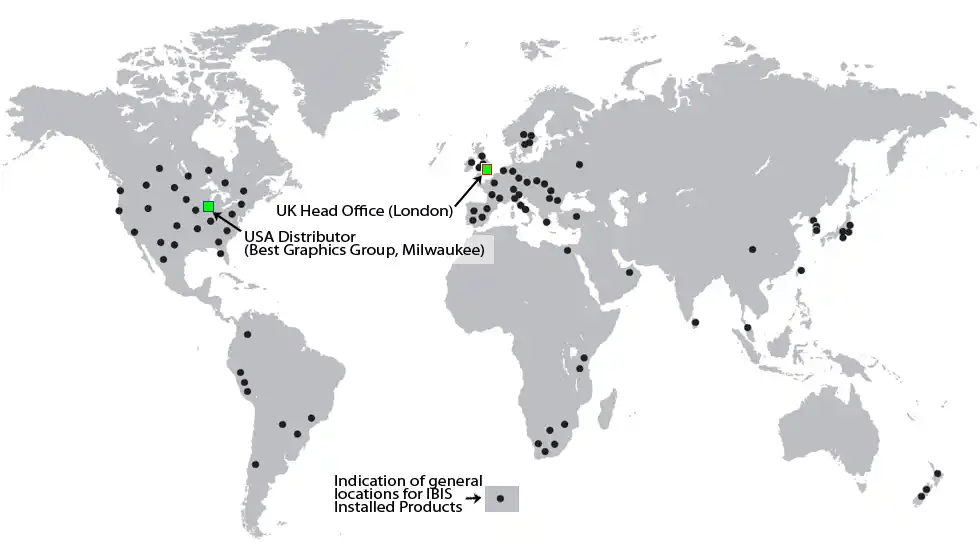

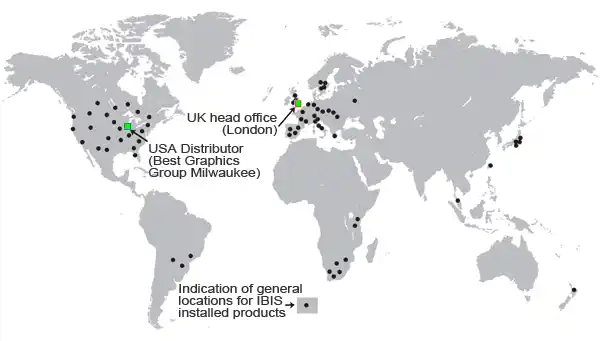

We are proud of our long-standing and continuing partnerships with all of the major continuous inkjet printer manufacturers and digital post-press suppliers. Over 100 digital-printers around the world are benefiting from IBIS book-finishing systems and many of these are ‘repeat buyers’. Our products are backed up with first-class customer training and support.

Our customer’s success is our own success!![]()

IBIS Location

We are based 30 miles (48km) from central London and only about 15 miles (24km) from Heathrow international airport.

Why buy from IBIS?

Reducing your production costs

- In-line or off-line operation

- Up to 2600 pages/min throughput (up to 14,000 books/hr output)

- Stitched and glued books up to 60mm (2.36") thick from the same machine

- Low running costs

Personization and book integrity

- IBIS digital finishing solutions allow rapid and easy personalization of books on the run

- 100% page integrity with absolute page and book tracking assured

- Accurate Management Reporting and diagnostics provide external control and visibility

Enhancing book quality

- Individual sheet folding for better lay-flat of saddle-bound books up to 200 pages

- ISG cold gluing available for increased strength and improved lay-flat

- Three-side trimming

Providing support and customization

- Highly skilled specialist field engineers

- Technical support by phone and email

- First level on-site support from digital printer vendors

- Large range of special options and added value features

- Special engineering to customize systems to your specific needs

Increasing up-time

- Very robust, high quality machine construction for 24/7 reliable operation

- Easy and quick to maintain

- Focus on operator and maintenance training

Smart-binder & SLB output

Saddle-stitched books up to 10mm (0.4") thick.

Saddle-glued books up to 10mm (0.4") thick - ISG cold glue

Square-back books made with cold and hot glue up to 60mm (2.36") thick

Square-back perfect-bound books up to 60mm (2.36") thick, hot-melt or PUR glue only

The Smart Label Binder (SLB) produces ECL booklets (Extended Content Labels), and other booklet types, directly from a digital printer or from digitally-printed paper rolls or from piles of digitally-printed cut sheets.

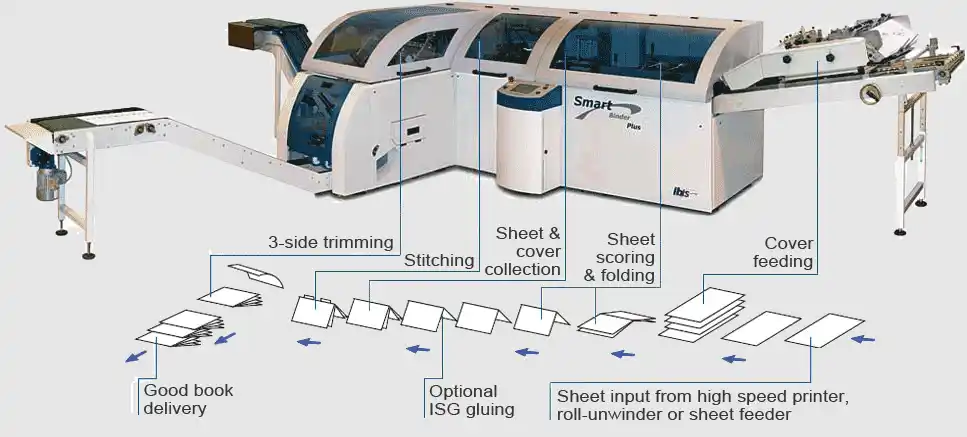

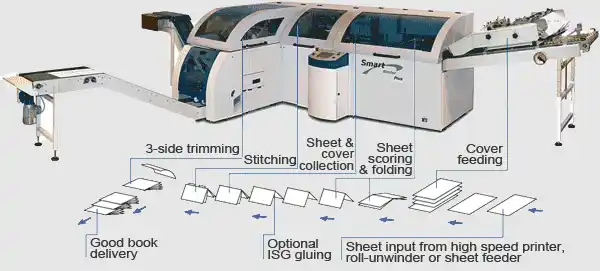

Smart-binder System

The Smart-binder systems are all based upon IBIS's unique saddle-stitcher which was launched in 2004. Model SB-2 produces wire-stitched books only.

Models SB-3 and the Smart Label-binder include ISG cold-gluing.

Smart-binder Plus HS SB-2 & SB-3

- For high-quality saddle-bound booklets

- On-the-run' re-loading of cover sheets

- SB-3 includes ISG cold gluing module to produce saddle-glued books

- Upgradable to SB-4 or SB-5

Smart Label-binder

- For the production of 'Extended Content Labels' (ECLs), when used together with an in-line tabbing machine.

- can run paper weights as light as 37gsm without requiring the folder F-100

Smart-binder Features

- In-line connection with highest speed digital printers, or off-line operation from a high speed sheet feeder, or roll unwinder

- Individual sheet folding for optimum book quality

- Cover and Insert sheet feeding

- Bar code tracking of all sheets and auto-rejection of bad books, to ensure integrity.

- Smart-Data Analysis System

- Book page count variable on the run

- Three-knife trimming with optional centre-knife

- Heavy duty construction for 24 x 7 operation

- Easy-to-use touch-screen controls

- Complete range of book format sizes

- Optional sheet dynamic micro-perforation and hole punching

- Optional sheet buffer for in-line applications

Smart-binder Configurations

View Smart Binder configurations (In-line, Near-line and Off-line) on the Smart-binder Description page

View the Smart-binder Configuration and Options Flow Diagram on the Smart-binder Description page.

IBIS Directors

Top

The IBIS team are based in High Wycombe, near London in the UK. The IBIS directors include Oxford and Cambridge engineering graduates.

John Cracknell (Managing Director)

With extensive experience as an Engineering Director at Heidelberg, AM, and Harris, John is one of the world's foremost authorities in the design and supply of innovative book-binding machinery.

Mark Firth (Engineering Director)

Specialist in Print Finishing system controls.

Karen Stanley (Finance Director)

Karen brings financial management expertise from both biotech and construction industries.

View the Contact IBIS page for other IBIS team members.

Our mission

Our Values

Commitment: We are committed to bringing success to our customers.

Openness: We communicate honestly and frankly.

Integrity: We conduct ourselves correctly and deliver what we promise at all times.

Technical excellence: We take pride in high standards of engineering and providing maximum benefits to end-users.

IBIS History Milestone Events

From 0 to 1 billion books

Top

History Milestone Events

2025 (Sept)

IBIS showcased its latest Smart Label-binder model at Labelexpo Barcelona in September 2025, demonstrating the production of Extended Content Label (ECL) booklets. The SLB was fed from piles of 45gsm printed sheets using a high-pile, high-speed sheet feeder, highlighting its capability to handle lightweight paper efficiently and reliably.

2025 (May)

IBIS partners with MML, UK to offer Smart-binders with customized in-line booklet inserting wrapping solutions, to ensure the highest possible security for examination booklet production.

2025 (Feb)

IBIS presents a new Smart-binder variant at Hunkeler InnovationDays 2025 - the Smart Label-binder (SLB). The SLB runs paper weights down to 40gsm (without requiring an additional folder) required for 'Extended Content Label' (ECL) booklet production.

2023 (Dec)

IBIS doubles production output by moving Smart-binder manufacture, assembly, testing and packing to our sub-contract partner company EDM based in 'Nizna' in the north of Slovakia.

2023 (Feb)

IBIS establishes a new market for Smart-binder Label printing and IBIS attends Hunkeler HID.

2022 (April)

IBIS open up a new market for Smart-binders in Eastern Europe (producing instruction manuals at 150 m/min web speed using lightweight paper).

2021 (Feb)

IBIS establishes a Smart-binder market in China for exam question paper production.

2020 (Aug)

IBIS participate in the Napco 2020 'virtual' Ink Jet Summit.

2019 (April)

IBIS's first sale of the Smart-binder system to the United Arab Emirates (UAE).

2018 (Sept)

IBIS launches the Smart-binder saddle-binder into the Korean market.

2017 (Nov)

IBIS forms a new sales and service distribution partnership with Best Graphics Inc, USA. Best Graphics will focus on IBIS 'Smart-binder' sales to the Digital print market.

2017 (May)

IBIS nominated for 'Best Case Study - Publishing' at Inkjet Summit 2017.

2015 (Dec)

New IBIS sheet-feeder SB-097 now allows in-line connected Smart-binders to also be fed from a sheet pile feeder.

2015 (Oct)

New IBIS line up for in-line Perfect Binding (hot glue binding) - the Sprint-binder PB-600R, Sprint-binder PB-1200R and the Sprint-binder PB-2000J.

2014 (Sept)

IBIS is awarded ‘top marks’ for exam booklet production, with around 30 Smart-binders producing stitched (or glued) and trimmed exam papers at customer locations all around the world.

2014 (May)

IBIS and Friedheim International sign UK distribution and support deal.

2014 (May)

IBIS celebrates 15 years of supplying high-end book finishing solutions for digital print.

2014 (Mar)

IBIS exhibits a Smart-binder SB-3 ‘Plus HS’ on its own stand at IPEX in London.

2013 (Oct)

New version ‘stretched’ Smart-binder (‘X’ model) launched for tabloid size output, or two-up A5 portrait.

2013 (Aug)

IBIS strengthens sales and support with new OEM partnerships.

2013 (July)

IBIS launches a new higher-performance Smart-binder ‘PLUS HS’ for production of variable page-count, digitally printed booklets.

2012 (Dec)

More than a billion booklets have been made on IBIS digital-saddle-stitchers around the world.

2012 (Sept)

IBIS celebrates the shipment of the 100th Smart-binder to a firm in Boston. IBIS continues to be the leading supplier of high-speed, variable page-count booklet systems to leading U.S. firms such as Principal Financial, Farmer's Insurance, Pearson, O'Neil Data Systems, Excellus, R.R. Donnelley, ifetouch, and many more.

2012 (June)

The first IBIS system with automatic on the run changeover between saddle-stitching and perfect binding is installed at a customer in Rome, Italy in-line with an Océ JetStream 2200 printer at 150 metres/min web speed.

2012 (May)

Drupa, Germany: IBIS launches the higher performance Smart-binder ‘Plus’ saddle stitcher and the new 1,500 books/hour Sprintbinder 4-clamp perfect binder.

2012 (June)

The first IBIS system with automatic on the run changeover between saddle-stitching and perfect binding is installed at a customer in Rome, Italy in-line with an Océ JetStream 2200 printer at 150 metres/min web speed.

2011 (May)

IBIS is granted a patent for its unique ISG saddle cold-glue system as used on the Smart-binder.

2009 (June)

IBIS celebrates its 10th birthday with an Open House and social events for staff and customers.

2006 (May)

IPEX, UK : Xerox and Delphax show the Smartbinder SB-4 which can produce saddle-stitched, ISG glued and perfect-bound books all in one system.

2006 (July)

Toppan Forms, Tokyo places IBIS's largest-ever single order for multiple Smart-binder SB-3 systems.

2004 (May)

The new IBIS Smart-binder SB-3 digital saddle-stitcher is launched on the Océ, Kern & Xerox stands, featuring IBIS’s patented Individual Sheet Gluing (ISG) binding system.

2003 (June)

Following worldwide success with 40 Digi-stitchers installed with Oce printers worldwide, IBIS opens up sales channels to other printer manufacturers in addition to Océ. These include IBM and Xerox.

2003 (April)

RR Donnelleys installs first Digistitcher in the USA in-line with Océ web printer.

2001 (Sept)

.

.IBIS moves into its new headquarters in High Wycombe UK.

2000 (May)

Drupa, Germany: The Digi-stitcher DST2 is launched to the world market at drupa in Düsseldorf.

2000 (April)

The first IBIS 'Digi-stitcher (the world’s first high speed in-line digital saddle-stitcher) is installed at The Stationery Office, London, to make stitched documents in-line with an Océ high speed web printer. This system produces ‘The London Gazette’ and other documents for the UK government.

1999 (Oct)

IBIS sign up to an exclusive sales contract agreed with Océ Printing Systems, Munich.

1999 (May)

John Cracknell, Mark Firth and Malcolm Allitt form IBIS Integrated Bindery Systems. The new IBIS engineering team design its first in-line digital-finishing product.