Smart-binder booklet integrity and control |

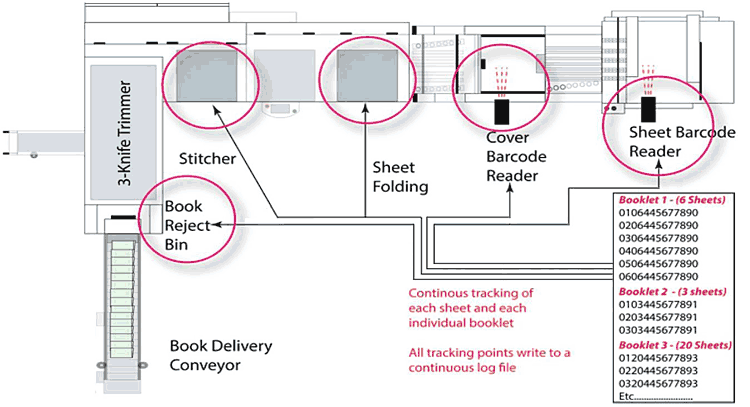

How the Smart-binder maintains booklet integrityThe Smart-binder reads every incoming sheet using a barcode (or 2D Datamatrix ) datareader. The type of reader is selected based upon the symbology that the customer intends to use in their print application. The Smart-binder can process all common barcode or 2D code symbologies. The code can be trimmed off from the finished booklet by the Smart-binder three-knife trimmer. Additionally, the Smart-binder can match separately-printed personalized covers with the booklet text. A reader in the cover feeder will compare the ID number printed on each cover with the ID number on the inside text sheets. The Smart-binder can be set to either stop when a mismatch or other fault is detected, or to reject the faulty booklet by placing it into a reject bin. The Smart-binder automatically checks that all sheets in each booklet contain the same 'ID' number to ensure that sheets from one booklet cannot be mixed with sheets from another booklet.

Each incoming sheet is tracked through the Smart-binder system and booklet data from the code printed on each sheet is written to an internal continuous log file in the Smart-binder's PC. The log file can be retrieved at any time to review the status of each booklet, and to create a reprint file, and is considered to be an "auditable" file. Smart-binders are used extensively in critical booklet applications such as examination booklets, HIPPA-compliant health care policy booklets, and even surgical instrument instruction booklets which are opened in the operating room. Other available Smart-binder control featuresSelective binding Selective perforation for sheet 'tear out' |