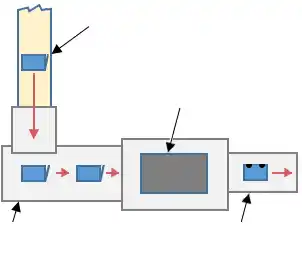

The BTM-730 tabber module applies one (or two) perforated circular tabs to the front edge of each booklet. This ensures that the booklets cannot be easily opened and read without breaking the tab(s).

The tabs add a high level of security to the booklet production process for applications such as examination test booklets.

The adhesive-backed tabs may be either plastic or paper material and are supplied on a roll.

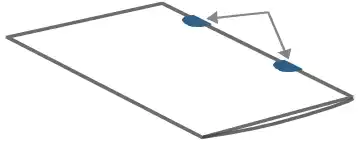

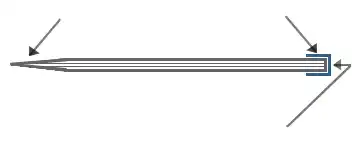

Booklets arrive from the Smart-binder with the spine leading. To apply the tabs to the front edge of the booklet the booklets must first be direction changed by 90 degrees:

The tabs are applied to the top side of the booklet and then folded underneath so they stick also to the underside.

This tabbing operation will function at the maximum Smart-binder booklet production speed of 7,000 booklets/hour (1-up production).

Note: After a booklet is opened by breaking the tab perforation it cannot be sealed closed again (it will be evident from the broken tab that the booklet has been opened).