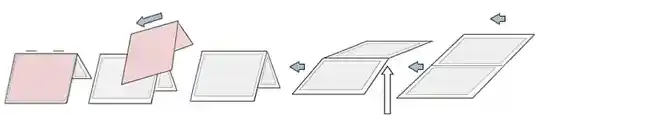

Flow diagram: 5½ x 8½" booklet production, 12" web

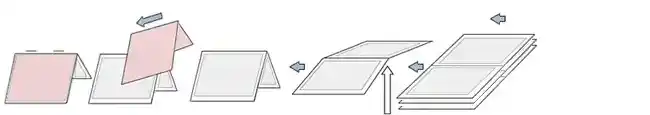

The 12" web is cut into sheets with a length circa 9". These 4-page sheets enter the Smart-binder (SB) infeed and the bar code on each sheet is read. Each sheet is accurately side-registered and the SB plow-folds each sheet down the center. ISG cold glue may be applied along the inside of each folded sheet (SB-3 only) and the sheets collect together on top of each other on the saddle (max approx 50 sheets, 200 pages, depending on paper weight).

If a separately-fed cover is needed, then this will feed automatically from the optional cover feeder CIF-102 and is folded on top of the inside sheets. Sheets are wire-stitched (if stitching is required), and 3-side trimmed to 5½ x 8½" size. Booklets may be stacked on the optional BSS-10 if required.

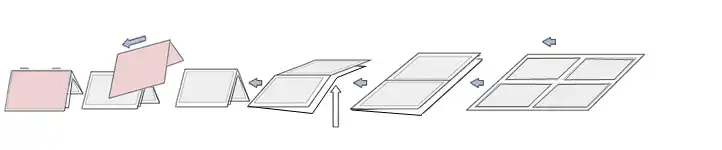

Flow diagram: 5½ x 8½" booklet production, 12" web

If it is possible to print on a 24" web then this can be slit into two 320mm wide rolls and each roll moved to the finishing system and processed as in 1.. above.

Eight page increments

The 12" web is cut into sheets circa 18" by the web-cutter. These 8-page sheets then enter the F-100 folder where they are buckle-folded in half. A line of cold glue dots is applied to the center of each sheet if cold-glue bound booklets are needed. The folded sheets are fed into the Smart-binder (SB). The bar code on each sheet is read. Each sheet is accurately side-registered and the SB plow-folds each sheet down the center. ISG cold glue may be applied along the inside of each folded sheet (SB-3 only) if cold-glue bound booklets are needed, and the sheets collect together on top of each other on the saddle (max approx 20 sheets, 160 pages, depending on paper weight).

Note: each sheet contains 8 printed pages (pp) so the total number of pp in each booklet must be divisible by 8, not 4

If a separately-fed cover is needed, then this will feed automatically from the optional cover feeder CIF-102 and is folded on top of the inside sheets. Sheets are wire-stitched (if stitching is required), and 3-side trimmed to 5½ x 8½" size. The SB trimmer head knife removes the head fold. Booklets may be stacked on the optional BSS-10 if required.

Flow diagram: 5½ x 8½" booklet production with F‑100, 12" web

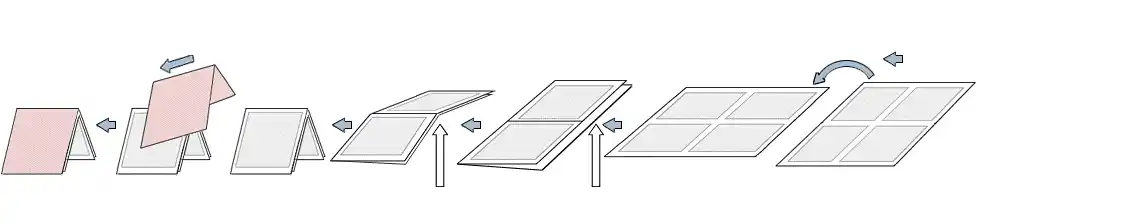

Eight page increments

The optional SRF-100 rotator/folder (consisting of SR-100 rotator and F-100 folder) is added between the web cutter and the IBIS Smart-binder (SB). The 18” wide web is cut into sheets with length 12” by the web-cutter (4 pages printed on each side, ie 8-page sheets). These are fed into the SR-100 rotator where they are rotated 90 degrees and, if cold-glue bound booklets are needed, a line of cold-glue dots is applied to the center of each sheet.The sheets are then fed into the F-100 buckle-folder where each sheet is folded in half and fed into the SB infeed.

The bar code on each sheet is read. Each sheet is accurately side-registered and the SB plow-folds each sheet down the center. ISG cold-glue may be applied along the inside of each folded sheet (SB-3 only) if cold-glue bound booklets are needed, and the sheets collect together on top of each other on the saddle (max approx 20 sheets, 160 pages, depending on paper weight). The SB trimmer head knife removes the head fold.

Note: each sheet contains 8 printed pages (pp) so the total number of pp in each booklet must be divisible by 8, instead of 4.

This solution is preferred if it is required to change between 5½ x 8½" and 8½ x 11" booklets. When producing 8½ x 11" booklets then the SRF-100 can be switched off so sheets pass straight through. Both 5½ x 8½" and 8½ x 11" booklets can be produced from the same 18” wide web. However sheets can only be rotated reliably if the stock weight is above 65 gsm.

Flow diagram: 5½ x 8½" production, with SR‑200 rotation and F‑100 folding, 18” web

This solution has the advantage of enabling booklets to be made with 4-page sheets (rather than 8-page) using an 18” wide web. However it is only be used to produce 5½ x 8½" booklets (it does not allow 8½ x 11" booklets to be produced from the web) and sheets can only be direction-changed reliably if the stock weight is above about 60 gsm. The web is slit down the middle and sheeted to produce 2 sheets (both size 9 x 12") side-by-side which are separated slightly and direction-changed by 90 degrees before entering the SB. The production process is then the same as option 1.

This option is paper weight dependent, please contact IBIS to discuss.

Video: 5½ x 8½" booklets from 18” web Data sheet: TUSDC‑100.

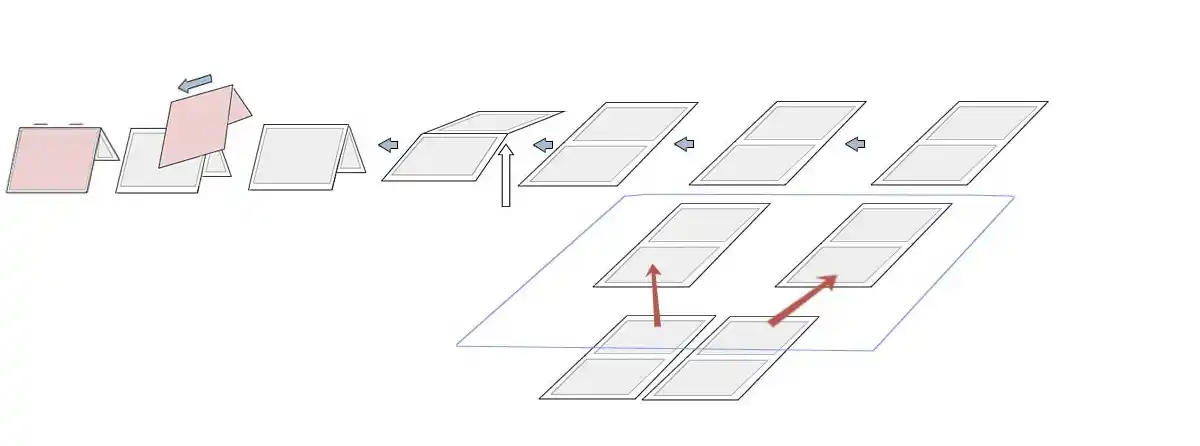

Flow diagram: 5½ x 8½" production with TUSDC‑100 2‑up sheet direction changer, 18” web

A sheet feed rate of 400 sheets/min is possible, depending on sheet size, paper weight and other variables

Printed 4-page sheets size circa 9 x12" are loaded into the SB-095 or SB-097 sheet pile-feeder which feeds from the top of the pile into the Smart-binder infeed. The bar code on each sheet is read and the sheet is side registered and center-plow folded. ISG cold-glue may be applied to each sheet if cold-glue bound booklets are required (SB-3 only) and the folded sheets collect together on top of each other on the saddle (max approx 50 sheets, 200 pages, depending on paper weight). If a separately-fed cover is needed, then this will feed automatically from the optional cover feeder CIF-102 and is folded on top of the inside sheets.

The sheets (and optional cover) are wire-stitched (if stitching is required), 3-side trimmed to 5½ x 8½" size and delivered in a shingled stream onto an indexing delivery conveyor. Booklets may be stacked using the optional BSS-10 stacker if required.

Video: Smart‑binder fed from pile feeder Data sheet: SB‑095 Data sheet: SB‑097

Flow diagram: Off‑line 5½ x 8½" production, 400 sheets/min sheet feed rate